- DOI: 10.1002/0470091282

- Corpus ID: 92006427

Thin Film Solar Cells: Fabrication, Characterization and Applications

- J. Poortmans , V. Arkhipov

- Published 15 September 2006

- Engineering, Physics, Materials Science

458 Citations

Aluminum-induced crystallization for thin-film polycrystalline silicon solar cells: achievements and perspective, photovoltaic applications of si and ge thin films deposited by pecvd, crystalline silicon thin-film solar cells on ceramic substrates, hydrogenated amorphous silicon-based thin film solar cell: optical, electrical and structural properties, processing and characterization of efficient thin-film polycrystalline silicon solar cells, progress in major thin-film solar cells: growth technologies, layer materials and efficiencies, c-si thin-films on carbon-related substrates: deposition and photovoltaic cells, towards high efficiency thin film solar cells, physical vapor deposition of novel thin-film solar absorbers.

- Highly Influenced

- 10 Excerpts

Towards high efficiency thin-film crystalline silicon solar cells: The roles of light trapping and non-radiative recombinations

2 references, thin‐film solar cells: an overview, energy pay-back time of photovoltaic energy systems: present status and prospects, related papers.

Showing 1 through 3 of 0 Related Papers

- {{subColumn.name}}

AIMS Materials Science

- {{newsColumn.name}}

- Share facebook twitter google linkedin

Overview of thin film deposition techniques

- Olayinka Oluwatosin Abegunde 1 ,

- Esther Titilayo Akinlabi 1 ,

- Oluseyi Philip Oladijo 1,2 , , ,

- Stephen Akinlabi 1 ,

- Albert Uchenna Ude 2

- 1. Department of Mechanical Engineering Science, University of Johannesburg, Johannesburg 2006, South Africa

- 2. Department of Chemical, Material and Metallurgical Engineering, Botswana International University of Science and Technology, Palapye, Botswana

- Received: 06 September 2018 Accepted: 23 January 2019 Published: 13 March 2019

- Full Text(HTML)

- Download PDF

- chemical vapor deposition ,

- physical vapor deposition ,

- surface coating ,

Citation: Olayinka Oluwatosin Abegunde, Esther Titilayo Akinlabi, Oluseyi Philip Oladijo, Stephen Akinlabi, Albert Uchenna Ude. Overview of thin film deposition techniques[J]. AIMS Materials Science, 2019, 6(2): 174-199. doi: 10.3934/matersci.2019.2.174

Related Papers:

| [1] | |

| [2] | , 3 Eds., Oxford: Elsevier. --> Martin P (2010) Deposition technologies: an overview, , 3 Eds., Oxford: Elsevier. |

| [3] | 200: 31–40. --> Halling J (1986) The tribology of surface coatings, particularly ceramics. 200: 31–40. doi: |

| [4] | 199: 139–144. --> Halling J, Nuri K (1985) The elastic contact of rough surfaces and its importance in the reduction of wear 199: 139–144. doi: |

| [5] | , William Andrew. --> Martin PM (2009) , William Andrew. |

| [6] | . --> Bräuer G (2014) Magnetron Sputtering, In: Hashmi S, . |

| [7] | , John Wiley & Sons. --> Martin P (2011) , John Wiley & Sons. |

| [8] | . --> Bhushan B, Gupta BK (1991) . |

| [9] | , CRC Press. --> Toyserkani E, Khajepour A, Corbin SF (2004) , CRC Press. |

| [10] | , IGI Global, 1–23. --> Mahamood RM, Akinlabi ET (2016) Laser Additive Manufacturing, In: Akinlabi ET, Mahamood RM, Akinlabi SA, , IGI Global, 1–23. |

| [11] | 262: 800–806. --> Kashani H, Amadeh A, Ghasemi H (2007) Room and high temperature wear behaviors of nickel and cobalt base weld overlay coatings on hot forging dies. 262: 800–806. doi: |

| [12] | 274: 177–181. --> Padaki M, Isloor AM, Nagaraja K, et al. (2011) Conversion of microfiltration membrane into nanofiltration membrane by vapour phase deposition of aluminium for desalination application 274: 177–181. doi: |

| [13] | , William Andrew. --> Mattox DM (2010) , William Andrew. |

| [14] | 253: 1522–1527. --> Park S, Ikegami T, Ebihara K, et al. (2006) Structure and properties of transparent conductive doped ZnO films by pulsed laser deposition. 253: 1522–1527. doi: |

| [15] | 513: 1–24. --> Helmersson U, Lattemann M, Bohlmark J, et al. (2006) Review Ionized physical vapor deposition (IPVD): A review of technology and applications. 513: 1–24. doi: |

| [16] | - and Ne -ion bombardment. 86: 1979–1982. --> Somogyvári Z, Langer GA, Erdélyi G, et al. (2012) Sputtering yields for low-energy Ar - and Ne -ion bombardment. 86: 1979–1982. doi: |

| [17] | 5: 69–77. --> Roy D, Halder N, Chowdhury T, et al. (2015) Effects of Sputtering Process Parameters for PVD Based MEMS Design. 5: 69–77. |

| [18] | , 3 Eds., Boston: William Andrew Publishing, 314–363. --> Carlsson J, Martin PM (2010) Chapter 7: Chemical Vapor Deposition, In: Martin PM, , 3 Eds., Boston: William Andrew Publishing, 314–363. |

| [19] | 17: 986–992. --> Voevodin A, O'Neill J, Prasad S, et al. (1999) Nanocrystalline WC and WC/a-C composite coatings produced from intersected plasma fluxes at low deposition temperatures. 17: 986–992. doi: |

| [20] | , William Andrew. --> Mattox DM (2010) , William Andrew. |

| [21] | 55: 3–10. --> Trajkovska-Petkoska A, Nasov I (2014) Surface engineering of polymers: Case study: PVD coatings on polymers 55: 3–10. doi: |

| [22] | 10: 1–83. --> Pretorius R, Marais T, Theron C (1993) Thin film compound phase formation sequence: An effective heat of formation model. 10: 1–83. doi: |

| [23] | |

| [24] | Thin Films Deposited by Low Temperature Reactive Magnetron Sputtering. 40: 340–343. --> Toku H, Pessoa RS, Maciel HS, et al. (2010) Influence of Process Parameters on the Growth of Pure-Phase Anatase and Rutile TiO Thin Films Deposited by Low Temperature Reactive Magnetron Sputtering. 40: 340–343. |

| [25] | , William Andrew. --> Seshan K (2012) , William Andrew. |

| [26] | , Noyes Publications. --> Bunshah RF (1982) , Noyes Publications. |

| [27] | . --> Mattox DM (1998) Atomistic Film Growth and Some Growth-Related Film Properties, . |

| [28] | , Wiley-VCH. --> Mahan JE (2000) , Wiley-VCH. |

| [29] | , McGraw-Hill Professional. --> Elshabini A, Elshabini-Riad AA, Barlow FD (1998) , McGraw-Hill Professional. |

| [30] | 253: 173–178. --> Holmberg K, Mathews A (1994) Coatings tribology: a concept, critical aspects and future directions. 253: 173–178. doi: |

| [31] | 56: 159–172. --> Kelly P, Arnell R (2000) Magnetron sputtering: a review of recent developments and applications 56: 159–172. doi: |

| [32] | 9: 287–292. --> Kelly P, Arnell R, Ahmed W (1993) Some recent applications of materials deposited by unbalanced magnetron sputiering. 9: 287–292. doi: |

| [33] | , Lamberts Academics Publishing. --> Ricciardi S (2012) , Lamberts Academics Publishing. |

| [34] | , 2 Eds., World Scientific. --> Cao G (2004) , 2 Eds., World Scientific. |

| [35] | , Walter de Gruyter. --> Leydecker S (2008) , Walter de Gruyter. |

| [36] | |

| [37] | , Springer Science & Business Media. --> Herman MA, Sitter H (2012) , Springer Science & Business Media. |

| [38] | 84: 3912–3918. --> Chen Y, Bagnall D, Koh H, et al. (1998) Plasma assisted molecular beam epitaxy of ZnO on c-plane sapphire: growth and characterization. 84: 3912–3918. doi: |

| [39] | |

| [40] | |

| [41] | films prepared by reactive evaporation. 371: 218–224. --> Mergel D, Buschendorf D, Eggert S, et al. (2000) Density and refractive index of TiO films prepared by reactive evaporation. 371: 218–224. doi: |

| [42] | films produced by reactive evaporation of various titanium–oxygen phases. 15: 2986–2991. --> Pulker HK, Paesold G, Ritter E (1976) Refractive indices of TiO films produced by reactive evaporation of various titanium–oxygen phases. 15: 2986–2991. doi: |

| [43] | Cu O thin films by activated reactive evaporation. 27: L91. --> Terashima T, Iijima K, Yamamoto K, et al. (1988) Single-crystal YBa Cu O thin films by activated reactive evaporation. 27: L91. doi: |

| [44] | 9: 1385–1388. --> Bunshah R, Raghuram A (1972) Activated reactive evaporation process for high rate deposition of compounds 9: 1385–1388. doi: |

| [45] | 80: 255–261. --> Bunshah R (1981) The activated reactive evaporation process: Developments and applications. 80: 255–261. doi: |

| [46] | |

| [47] | 2015: 22–26. --> Seyfert U, Heisig U, Teschner G, et al. (2015) 40 Years of Industrial Magnetron Sputtering in Europe. 2015: 22–26. |

| [48] | , Noyes Publications/William Andrew Publishing. --> Seshan K (2001) , Noyes Publications/William Andrew Publishing. |

| [49] | 420: 70–75. --> Teixeira V, Cui H, Meng L, et al. (2002) Amorphous ITO thin films prepared by DC sputtering for electrochromic applications. 420: 70–75. |

| [50] | O –SnO transparent and conductive films prepared by d.c. sputtering using high density ceramic targets. 445: 229–234. --> Utsumi K, Iigusa H, Tokumaru R, et al. (2003) Study on In O –SnO transparent and conductive films prepared by d.c. sputtering using high density ceramic targets. 445: 229–234. |

| [51] | O thin films on (001)-SrTiO substrates by dc sputtering 119: 7–14. --> Gómez A, Galeano A, Saldarriaga W, et al. (2015) Deposition of YBaCo O thin films on (001)-SrTiO substrates by dc sputtering 119: 7–14. doi: |

| [52] | |

| [53] | 4: 468–471. --> You T, Niwa O, Tomita M, et al. (2002) Characterization and electrochemical properties of highly dispersed copper oxide/hydroxide nanoparticles in graphite-like carbon films prepared by RF sputtering method. 4: 468–471. doi: |

| [54] | 5: 2490–2496. --> Torng C, Sivertsen JM, Judy JH, et al. (1990) Structure and bonding studies of the C: N thin films produced by rf sputtering method. 5: 2490–2496. doi: |

| [55] | 56: 159–172. --> Kelly PJ, Arnell RD (2000) Magnetron sputtering: a review of recent developments and applications. 56: 159–172. doi: |

| [56] | . --> Constantin DG, Apreutesei M, Arvinte R, et al. (2011) Magnetron sputtering technique used for coatings deposition; technologies and applications. . |

| [57] | |

| [58] | |

| [59] | 112: 170–176. --> Arnell RD, Kelly PJ (1999) Recent advances in magnetron sputtering. 112: 170–176. doi: |

| [60] | 100: 280–286. --> Musil J (1998) Recent advances in magnetron sputtering technology. 100: 280–286. |

| [61] | |

| [62] | 316: 152–157. --> Ishihara M, Li S, Yumoto H, et al. (1998) Control of preferential orientation of AlN films prepared by the reactive sputtering method. 316: 152–157. doi: |

| [63] | |

| [64] | 122: 290–293. --> Kouznetsov V, Macák K, Schneider JM, et al. (1999) A novel pulsed magnetron sputter technique utilizing very high target power densities. 122: 290–293. doi: |

| [65] | 204: 1661–1684. --> Sarakinos K, Alami J, Konstantinidis S (2010) High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. 204: 1661–1684. doi: |

| [66] | 483: 530–534. --> Alami J, Bolz S, Sarakinos K (2009) High power pulsed magnetron sputtering: Fundamentals and applications. 483: 530–534. doi: |

| [67] | , Noyes Publications --> Wasa K, Hayakawa S (1992) , Noyes Publications |

| [68] | , Springer Science & Business Media. --> Wasa K, Kitabatake M, Adachi H (2004) , Springer Science & Business Media. |

| [69] | , Norwich, NY: William Andrew Publishing, 17–69. --> Wasa K, Kitabatake M, Adachi H (2004) Thin Film Processes, In: Wasa K, Kitabatake M, Adachi H, , Norwich, NY: William Andrew Publishing, 17–69. |

| [70] | 186: 227–233. --> Liu X, Poon RWY, Kwok SCH, et al. (2004) Plasma surface modification of titanium for hard tissue replacements. 186: 227–233. doi: |

| [71] | 47: 49–121. --> Liu X, Chu PK, Ding C (2005) Surface modification of titanium, titanium alloys, and related materials for biomedical applications. 47: 49–121. |

| [72] | for photocatalytic applications [PhD thesis]. Curtin University. --> Albetran HMM (2016) Synthesis and characterisation of nanostructured TiO for photocatalytic applications [PhD thesis]. Curtin University. |

| [73] | |

| [74] | and/or SiC for use in photoelectrochemical cells: A review of the material characteristics, synthesis and recent applications. 29: 56–68. --> Pessoa R, Fraga M, Santos L, et al. (2015) Nanostructured thin films based on TiO and/or SiC for use in photoelectrochemical cells: A review of the material characteristics, synthesis and recent applications. 29: 56–68. doi: |

| [75] | 147: 1538–1550. --> Kommu S, Wilson GM, Khomami B (2000) A Theoretical/Experimental Study of Silicon Epitaxy in Horizontal Single‐Wafer Chemical Vapor Deposition Reactors. 147: 1538–1550. doi: |

| [76] | 133: 1476. --> Pedersen H, Elliott SD (2014) Studying chemical vapor deposition processes with theoretical chemistry 133: 1476. doi: |

| [77] | |

| [78] | |

| [79] | |

| [80] | |

| [81] | 25: L519. --> Hirose Y, Terasawa Y (1986) Synthesis of diamond thin films by thermal CVD using organic compounds. 25: L519. doi: |

| [82] | 35: 155–159. --> Petzoldt F, Piglmayer K, Kräuter W, et al. (1984) Lateral growth rates in laser CVD of microstructures 35: 155–159. doi: |

| [83] | /Cr O films grown by Laser-CVD. 247: 423–428. --> Sousa P, Silvestre A, Popovici N, et al. (2005) Morphological and structural characterization of CrO /Cr O films grown by Laser-CVD. 247: 423–428. doi: |

| [84] | 18: 3181–3184. --> Matsui S, Kaito T, Fujita J, et al. (2000) Three-dimensional nanostructure fabrication by focused-ion-beam chemical vapor deposition. 18: 3181–3184. doi: |

| [85] | thin film by double-excitation photo-CVD. 26: 805. --> Inoue K, Michimori M, Okuyama M, et al. (1987) Low temperature growth of SiO thin film by double-excitation photo-CVD. 26: 805. |

| [86] | 139: 320–328. --> Tanimoto S, Matsui M, Kamisako K, et al. (1992) Investigation on leakage current reduction of photo‐CVD tantalum oxide films accomplished by active oxygen annealing. 139: 320–328. doi: |

| [87] | |

| [88] | 4: 317–321. --> Li Y, Mann D, Rolandi M, et al. (2004) Preferential growth of semiconducting single-walled carbon nanotubes by a plasma enhanced CVD method. 4: 317–321. doi: |

| [89] | 303: 222–225. --> Hozumi A, Takai O (1997) Preparation of ultra water-repellent films by microwave plasma-enhanced CVD 303: 222–225. doi: |

| [90] | , Elsevier. --> Hitchman ML, Jensen KF (1993) , Elsevier. |

| [91] | 122: 147–159. --> Graniel O, Weber M, Balme S, et al. (2018) Atomic layer deposition for biosensing applications. 122: 147–159. doi: |

| [92] | |

| [93] | 70: 1182–1191. --> Guo HC, Ye E, Li Z, et al. (2017) Recent progress of atomic layer deposition on polymeric materials 70: 1182–1191. doi: |

| [94] | 110: 111–131. --> George SM (2009) Atomic layer deposition: an overview. 110: 111–131. |

| [95] | 113: 2. --> Miikkulainen V, Leskelä M, Ritala M, et al. (2013) Crystallinity of inorganic films grown by atomic layer deposition: Overview and general trends. 113: 2. |

| [96] | 44: 29–35. --> Bohr MT, Chau RS, Ghani T, et al. (2007) The high-k solution. 44: 29–35. doi: |

| [97] | 338: 34–48. --> Yan B, Li X, Bai Z, et al. (2017) A review of atomic layer deposition providing high performance lithium sulfur batteries. 338: 34–48. doi: |

| [98] | 54: 147–156. --> Ozer N, Lampert CM (1998) Electrochromic characterization of sol–gel deposited coatings. 54: 147–156. doi: |

| [99] | 10: 225–231. --> Ghoranneviss ZG (2016) Effects of various deposition times and RF powers on CdTe thin film growth using magnetron sputtering. 10: 225–231. doi: |

| [100] | , INTECH Open Access Publisher. --> Alfonso E, Cubillos G, Olaya J (2012) , INTECH Open Access Publisher. |

| [101] | , New York: Academic Press. --> Lewis B, Anderson JC (1978) , New York: Academic Press. |

| [102] | , Springer, 341–404. --> Venables JA, Spiller GDT (1983) Nucleation and growth of thin films, In: , Springer, 341–404. |

| [103] | 4: 209–218. --> Lewis B, Campbell D (1967) Nucleation and initial-growth behavior of thin-film deposits. 4: 209–218. doi: |

| [104] | 26: 5–23. --> Lane G, Anderson J (1975) The nucleation and initial growth of gold films deposited onto sodium chloride by ion-beam sputtering. 26: 5–23. doi: |

| [105] | 28: 653–660. --> Movchan B, Demchishin A (1969) Structure and properties of thick condensates of nickel, titanium, tungsten, aluminum oxides, and zirconium dioxide in vacuum. 28: 653–660. |

| [106] | 7: 239–260. --> Thornton JA (1977) High rate thick film growth. 7: 239–260. doi: |

| [107] | 2: 500–503. --> Messier R, Giri A, Roy R (1984) Revised structure zone model for thin film physical structure. 2: 500–503. doi: |

| [108] | |

| [109] | |

| [110] | 8: 325. --> Wang B, Fu X, Song S, et al. (2018) Simulation and Optimization of Film Thickness Uniformity in Physical Vapor Deposition. 8: 325. doi: |

| [111] | 54: 270–280. --> Divi S, Chatterjee A (2014) Study of Silicon Thin Film Growth at High Deposition Rates Using Parallel Replica Molecular Dynamics Simulations 54: 270–280. doi: |

| [112] | , 23: 1–28. --> Allen MP (2004) Introduction to molecular dynamics simulation, In: Attig N, Binder K, Grubmuller H, , 23: 1–28. |

| [113] | , Germany: FZJ-ZAM-IB. --> Sutmann G (2002) , Germany: FZJ-ZAM-IB. |

| [114] | , 7–10. --> Rasoulian S, Ricardez-Sandoval LA (2015) Worst-case and distributional robustness analysis of a thin film deposition process. , 7–10. |

| [115] | 326: 15–25. --> Li J, Croiset E, Ricardez-Sandoval L (2015) Carbon nanotube growth: First-principles-based kinetic Monte Carlo model. 326: 15–25. doi: |

| [116] | 19: 441. --> Family F (1986) Scaling of rough surfaces: effects of surface diffusion. 19: 441. doi: |

| [117] | 66: 2899. --> Tang L, Nattermann T (1991) Kinetic roughening in molecular-beam epitaxy. 66: 2899. doi: |

| [118] | 138: 244112. --> Bhute VJ, Chatterjee A (2013) Building a kinetic Monte Carlo model with a chosen accuracy. 138: 244112. doi: |

| [119] | 138: 084103. --> Bhute VJ, Chatterjee A (2013) Accuracy of a Markov state model generated by searching for basin escape pathways. 138: 084103. doi: |

| [120] | 58: 3115–3129. --> Lou Y, Christofides PD (2003) Estimation and control of surface roughness in thin film growth using kinetic Monte-Carlo models. 58: 3115–3129. doi: |

| [121] | 11: 85–98. --> Theodoropoulou A, Adomaitis RA, Zafiriou E (1998) Model reduction for optimization of rapid thermal chemical vapor deposition systems. 11: 85–98. doi: |

| [122] | Ge Thin Film Chemical–Vapor Deposition. 20: 114–125. --> Middlebrooks SA, Rawlings JB (2007) Model Predictive Control of Si Ge Thin Film Chemical–Vapor Deposition. 20: 114–125. doi: |

| [123] | 34: 70–81. --> Rasoulian S, Ricardez-Sandoval LA (2015) Robust multivariable estimation and control in an epitaxial thin film growth process under uncertainty. 34: 70–81. doi: |

| [124] | 89: 1324–1341. --> Ricardez‐Sandoval LA (2011) Current challenges in the design and control of multiscale systems. 89: 1324–1341. doi: |

| [125] | 30: 1–61. --> Vlachos DG (2005) A review of multiscale analysis: examples from systems biology, materials engineering, and other fluid–surface interacting systems. 30: 1–61. doi: |

| [126] | 119: 465–479. --> Chaffart D, Ricardez-Sandoval LA (2018) Optimization and control of a thin film growth process: A hybrid first principles/artificial neural network based multiscale modelling approach. 119: 465–479. doi: |

| [127] | 3: 562–569. --> Jensen KF, Rodgers ST, Venkataramani R (1998) Multiscale modeling of thin film growth. 3: 562–569. doi: |

| [128] | 26: 182–189. --> Baumann F, Chopp D, De La Rubia TD, et al. (2001) Multiscale modeling of thin-film deposition: applications to Si device processing 26: 182–189. doi: |

| [129] | 72: 405–410. --> Zhang P, Zheng X, Wu S, et al. (2004) Kinetic Monte Carlo simulation of Cu thin film growth. 72: 405–410. doi: |

| [130] | 273: 374–392. --> Evans RD, Ricardez-Sandoval LA (2014) Multi-scenario modelling of uncertainty in stochastic chemical systems. 273: 374–392. doi: |

| [131] | 60: 128–140. --> Chaffart D, Ricardez-Sandoval LA (2017) Robust dynamic optimization in heterogeneous multiscale catalytic flow reactors using polynomial chaos expansion. 60: 128–140. doi: |

| [132] | 140: 90–103. --> Rasoulian S, Ricardez-Sandoval LA (2016) Stochastic nonlinear model predictive control applied to a thin film deposition process under uncertainty 140: 90–103. doi: |

| [133] | 136: 38–49. --> Rasoulian S, Ricardez-Sandoval LA (2015) A robust nonlinear model predictive controller for a multiscale thin film deposition process. 136: 38–49. doi: |

| [134] | 35: 299–315. --> Allgöwer F, Findeisen R, Nagy ZK (2004) Nonlinear model predictive control: From theory to application. 35: 299–315. |

| [135] | 64: 3668–3682. --> Hu G, Orkoulas G, Christofides PD (2009) Modeling and control of film porosity in thin film deposition. 64: 3668–3682. doi: |

| [136] | 56: C65–C70. --> Li C, Song S, Gibson D, et al. (2017) Modeling and validation of uniform large-area optical coating deposition on a rotating drum using microwave plasma reactive sputtering. 56: C65–C70. doi: |

| [137] | 114: 158–170. --> Heirung TAN, Paulson JA, O'Leary J, et al. (2018) Stochastic model predictive control-how does it work? 114: 158–170. doi: |

| [138] | 121: 148–157. --> Koronaki E, Gkinis P, Beex L, et al. (2018) Classification of states and model order reduction of large scale Chemical Vapor Deposition processes with solution multiplicity. 121: 148–157. |

| [139] | 54: 270–280. --> Divi S, Chatterjee A (2014) Study of Silicon Thin Film Growth at High Deposition Rates Using Parallel Replica Molecular Dynamics Simulations 54: 270–280. doi: |

- This work is licensed under a Creative Commons Attribution-NonCommercial-Share Alike 4.0 Unported License. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/4.0/ -->

Supplements

Access History

- Corresponding author: University of Johannesburg; University of Johannesburg; Material and Metallurgical Engineering;

Reader Comments

- © 2019 the Author(s), licensee AIMS Press. This is an open access article distributed under the terms of the Creative Commons Attribution License ( http://creativecommons.org/licenses/by/4.0 )

通讯作者: 陈斌, [email protected]

沈阳化工大学材料科学与工程学院 沈阳 110142

Article views( 29905 ) PDF downloads( 16436 ) Cited by( 100 )

Figures and Tables

Figures( 4 )

Associated material

Other articles by authors.

- Olayinka Oluwatosin Abegunde

- Esther Titilayo Akinlabi

- Oluseyi Philip Oladijo

- Stephen Akinlabi

- Albert Uchenna Ude

Related pages

- on Google Scholar

- Email to a friend

- Order reprints

Export File

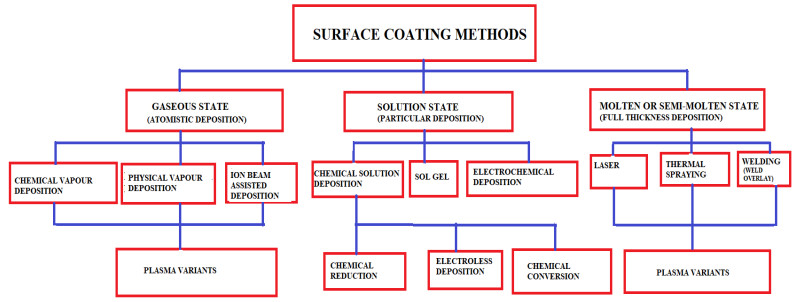

- Figure 1. Variants of thin film deposition techniques

- Figure 2. Variants of Physical Vapour Deposition

- Figure 3. Variants of Chemical Vapour Deposition

- Figure 4. (A) Movchan and Demchishin Structure Zone Model SZM, (B) Thornton Structure Zone Model SZM [ 26 ]

Some problems in thin-film flow

Downloadable content.

- Mitchell, Andrew James

- Strathclyde Thesis Copyright

- University of Strathclyde

- Doctoral (Postgraduate)

- Doctor of Philosophy (PhD)

- Department of Mathematics and Statistics

- Thin-film flows are ubiquitous in nature and industry, and this thesis considersthree different thin-film flow problems that are inspired by and relevant to a number of real-world situations. Firstly, we consider the steady and unsteady coating flow of a thin film of viscous fluid on the outside of a uniformly rotating horizontal circular cylinder in the presence of an irrotational airflow with circulation. In particular, it is shown that steady full-film solutions corresponding to a thin film of fluid that covers the entire cylinder are possible only when the flux and mass of the fluid do not exceed critical values, which are determined in terms of the speed of the far-field airflow and the circulation of the airflow. Furthermore, a long-time analysis shows that unsteady full-film solutions are unconditionally stable. Secondly, we consider the squeeze-film flow of a thin film of fluid in the gap between an impermeable disk and an open-base porous bed, subject to a constant load. In particular, we determine the finite time required for the impermeable disk and the porous bed to contact, and the behaviour of the particle paths and penetration depths of the fluid within the porous bed. These are described in terms of the permeability and porosity of the porous bed and the slip length at the interface between the fluid and porous bed. In particular, in the asymptotic limits of small and large permeability, the contact time, particle paths, and penetration depths exhibit qualitatively different behaviour. Finally, we consider the steady flow of a thin rivulet of evaporating fluid down an inclined substrate. In particular, for three different models of evaporation, we analyse the variation of the length, width and contact angle of the rivulet as theparameters appearing in the problem vary, such as the input flux of the rivulet, the angle of inclination of the substrate, and the parameters of the relevant model of evaporation. In particular, it is shown that, rather surprisingly, the length of the rivulet only depends weakly on the mode of evaporation.

- Wilson, Stephen

- Duffy, Brian R.

- Doctoral thesis

- 10.48730/phag-3n43

| Thumbnail | Title | Date Uploaded | Visibility | Actions |

|---|---|---|---|---|

| 2024-05-29 | Public |

Journal of Materials Chemistry C

Synthesis of air-stable 1t crs2 thin films and their application in high-performance floating-gate memory.

Two-dimensional van der Waals materials, with atomic-level thickness and unique electronic structures, have tremendous potential in electronic device applications, making them highly desirable for research in high-performance non-volatile memory. Here, we report a method for the van der Waals epitaxial growth of air-stable and uniformly distributed thin films of 1T CrS2 single crystal, based on a simple chemical vapor deposition technique using a binary metal precursor co-reaction growth mechanism controlled by the evaporation rate of the precursor. The corresponding 1T CrS2 electronic devices can maintain their electrical performance without degradation for up to one month in air. Based on this, we have constructed a floating-gate memory device with a full van der Waals heterostructure, exhibiting a large storage window ratio (approximately 79%), a high on/off ratio (107), and stability for over 1000 cycles. The device demonstrates excellent multi-level data storage stability and can be optically programmed with stable operation using 532nm laser pulses, showcasing outstanding optoelectronic storage performance. The excellent electrical stability of these two-dimensional materials, the non-volatile nature of the devices, and the stable multi-level storage characteristics present enormous potential for the integration of high-performance non-volatile memory.

Supplementary files

- Supplementary information PDF (1315K)

Article information

Download citation, permissions.

Y. Yao, B. Wang, Y. Li, W. Hong, X. He, Z. Fu, Q. Cai and W. Liu, J. Mater. Chem. C , 2024, Accepted Manuscript , DOI: 10.1039/D4TC00903G

To request permission to reproduce material from this article, please go to the Copyright Clearance Center request page .

If you are an author contributing to an RSC publication, you do not need to request permission provided correct acknowledgement is given.

If you are the author of this article, you do not need to request permission to reproduce figures and diagrams provided correct acknowledgement is given. If you want to reproduce the whole article in a third-party publication (excluding your thesis/dissertation for which permission is not required) please go to the Copyright Clearance Center request page .

Read more about how to correctly acknowledge RSC content .

Social activity

Search articles by author.

This article has not yet been cited.

Advertisements

IMAGES

VIDEO

COMMENTS

thin films in the solar sector, thin film transistor industry among others [37, 38]. Phy sical properties such as hardness and Y oung' s modulus are usually chara cter- ized drawin g on the nan ...

This Licenciate Thesis is a part of my Ph.D. studies in the Thin Film Physics Group at the Department of Physics, Chemistry, and Biology (IFM) at Linköping University. The aim of my research is to synthesize and characterize MAX phases with novel properties. The work has been performed in cooperation with RWTH Aachen University (Germany),

film and nanostructure growth. Importantly, for the thin film growth, chemical bath deposition (CBD) with various post-deposition annealing temperatures used to was grow porous thin films with different composition and degree of crystallinity; while sputtering with substrate heating used to deposit thin filmwass with excellent quality and

contribute to the optimization of thin film deposition processes and the enhancement of device performance in cryoelectronic applications. 1.2 Objectives and scope There are four objectives in this thesis. 1.Characterization of thin SiN films from a standard process: The primary objective is

materials could not achieve. This chapter will discuss the thin film deposition technology and applications. 1.1 Thin Film Deposition Technology Basically, thin film deposition can be realized by physical vapor deposition (PVD) and chemical vapor deposition (CVD) methods. It is easy to distinguish PVD from CVD

PDF | On May 19, 2020, Vidit Pandey and others published Thin Film, Its synthesis and Applications | Find, read and cite all the research you need on ResearchGate ... Thesis (M.S.)--Southwest ...

The surface morphology of the annealed thin films was studied by SEM which showed dense and homogeneous packing of grain with grain size ~1.25µm. Temperature and frequency dependence of dielectric behavior of PCT thin films have been studied. Thickness of the PCT thin film was measured and found to be ~100nm.

thin-film solar cells in addition to silicon nanowire based thin-film resistors, diodes and transistors as model systems. The transfer yield is improved to 100%, and the transferred ... My thesis work benefits from the numerous help of my incredibly talented colleagues. I thank my fellow labmates in Zheng's Group: Dr. In-Sun Cho, Dr. Dong-Rip ...

Abstract. Thin-film lithium niobate integrated photonics is a compelling platform for highly integrated electro-optic systems. The platform features compact, high-bandwidth phase modulators which can operate at CMOS compatible voltages, together with low optical loss, enabling photonic systems with large numbers of cascaded modulating elements.

MTS devices can be used as thin film energy harvesters in chip-based IoT sensors. The second section of this thesis focuses on the mechanisms of cyclic lithiation and delithiation of RuO2. RuO2 is a candidate cathode material for next-generation thin film lithium ion batteries (TF-LIBs), due to its relatively large capacity (~5x LiCoO2) and its

The thin film deposition process is a fundamental step in many applications, which refers to applying a thin layer of any substance on a surface, whether a substrate or already deposited layers ...

MICROWAVE PERFORMANCE OF THIN-FILM TECHNOLOGIES ON LTCC by ANDREW FUND B.S., Kansas State University 2005 A THESIS submitted in partial fulfillment of the requirements for the degree MASTER OF SCIENCE Department of Electrical Engineering College of Engineering KANSAS STATE UNIVERSITY

in the monolayer regime, and both the kinetics of thin film deposition and the microstructure in the multilayer regime, evidenced by results from ellipsometry and atomic force microscopy (AFM). Promising performance characteristics have been obtained for organic thin film transistors (OTFTs) fabricated from

Hu, Yaowen. 2023. Coupled-resonators on thin-film lithium niobate: Photonic multi-level system with electro-optic transition. Doctoral dissertation, Harvard University Graduate School of Arts and Sciences. ... In this thesis, we will discuss our implementation of photonic coupler-resonator . iv devices on thin -film lithium niobate. We ...

The thesis includes the results obtained during my Ph.D. study at the Department of Physics and NTIS, European Centre of Excellence, University of West Bohemia, since January 2013. This research was financially supported by the projects SGS‒2013‒045 (2013‒2015): New thin-film

Thin film solar cells are a promising approach for terrestrial and space photovoltaics and offer a wide variety of choices in terms of the device design and fabrication, but it would surely be determined by the simplicity of manufacturability and the cost per reliable watt. Expand. 1,070. PDF.

electronics. Thin film transistors (TFTs) are often viewed as a building block for more complex electronic device, however, lack of proper characterization of these devices using these novel carbon-based materials is preventing their large-scale adoption. This thesis has two sections; in the first section I explored and improved a novel electrical

ess measurement is nearly the resolution limit of the microscope system. For optical microscopes, it is 400nm and for scanning electron microscopes, 2 nm and tra. ission electron microscopes (TEM), the resolution limit is below 1 nm. 4 In this work we have developed an alternative method for thin fil. thickness measurement using Energy ...

promise is thin-film superlattices, where each n-type and p-type film is composed of hundreds of thin alternating layers of two materials. In this work, we investigate n-type films composed of alternating silicon (Si) and silicon-carbide (SiC), and p-type films composed of alternating layers of two types of boron-carbide, B 4 C and B 9 C.

Steps of Thin Film Growth. Absorption (physisorption) Surface diffusion. Chemical bond formation (chemisorption) Molecule-molecule. Substrate-molecule 2 3 4 6 1 5. Nucleation. Microstructure formation. Crystal structure.

Pretorius R, Marais T, Theron C (1993) Thin film compound phase formation sequence: An effective heat of formation model. Mater Sci Rep 10: 1-83. doi: 10.1016/0920-2307(93)90003-W [23] Alami J (2005) Plasma Characterization Thin Film Growth and Analysis in Highly Ionized Magnetron Sputtering [PhD thesis]. Linköping University.

Abstract. Thin-film flows are ubiquitous in nature and industry, and this thesis considersthree different thin-film flow problems that are inspired by and relevant to a number of real-world situations. Firstly, we consider the steady and unsteady coating flow of a thin film of viscous fluid on the outside of a uniformly rotating horizontal ...

Here, a general classification for thin film thermoelectric materials varied by material compositions, and thermoelectric properties depended on different measurement technique.

Here, we report a method for the van der Waals epitaxial growth of air-stable and uniformly distributed thin films of 1T CrS2 single crystal, based on a simple chemical vapor deposition technique using a binary metal precursor co-reaction growth mechanism controlled by the evaporation rate of the precursor.