Advertisement

- Publications

This site uses cookies to enhance your user experience. By continuing to use this site you are agreeing to our COOKIE POLICY .

Grab your lab coat. Let's get started

Create an account below to get 6 c&en articles per month, receive newsletters and more - all free., it seems this is your first time logging in online. please enter the following information to continue., as an acs member you automatically get access to this site. all we need is few more details to create your reading experience., not you sign in with a different account..

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Already have an ACS ID? Log in here

The key to knowledge is in your (nitrile-gloved) hands

Access more articles now. choose the acs option that’s right for you..

Already an ACS Member? Log in here

$0 Community Associate

ACS’s Basic Package keeps you connected with C&EN and ACS.

- Access to 6 digital C&EN articles per month on cen.acs.org

- Weekly delivery of the C&EN Essential newsletter

$80 Regular Members & Society Affiliates

ACS’s Standard Package lets you stay up to date with C&EN, stay active in ACS, and save.

- Access to 10 digital C&EN articles per month on cen.acs.org

- Weekly delivery of the digital C&EN Magazine

- Access to our Chemistry News by C&EN mobile app

$160 Regular Members & Society Affiliates $55 Graduate Students $25 Undergraduate Students

ACS’s Premium Package gives you full access to C&EN and everything the ACS Community has to offer.

- Unlimited access to C&EN’s daily news coverage on cen.acs.org

- Weekly delivery of the C&EN Magazine in print or digital format

- Significant discounts on registration for most ACS-sponsored meetings

Your account has been created successfully, and a confirmation email is on the way.

Your username is now your ACS ID.

Environment

Five green chemistry success stories, the 2017 green chemistry challenge awards recognize chemical innovations that prevent pollution and promote sustainability, by stephen k. ritter, june 26, 2017 | a version of this story appeared in volume 95, issue 26.

- How can companies recycle wind turbine blades?

- Can Europe’s chemical industry survive net zero?

- Are fluorinated drugs PFAS?

- Periodic Graphics: Summer hair color changes

- What is ball lightning, a reality or myth?

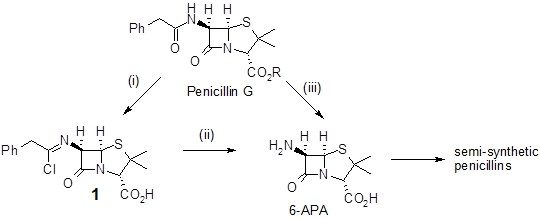

The 12 Principles of Green Chemistry are a how-to guide written 20 years ago for chemists and chemical engineers. They provide insight on developing new chemicals and chemical processes and revitalizing existing ones so that they achieve their desired function while being environmentally and economically friendly. It’s a creative challenge to put the 12 principles into action.

Five technologies that have succeeded in meeting that creative challenge have received 2017 green chemistry challenge awards . merck, dow chemical , koehler , amgen, bachem, unienergy technologies, and university of pennsylvania chemistry professor eric j. schelter were honored for their achievements at a ceremony held on june 12 at the national academy of sciences in washington, d.c. the award winners presented details of their technologies the next day at the annual green chemistry & engineering conference ., the environmental protection agency established the awards program in 1995 to help achieve federal goals set by the provisions of the pollution prevention act of 1990. these include reducing toxicity of chemical products, saving water or energy, and reducing waste even if it’s not hazardous. the program is administered by epa’s green chemistry program and is supported by partners including the american chemical society and its green chemistry institute ., “the green chemistry challenge awards highlight the importance of sustainable chemistry and its impact across a range of disciplines,” says princeton university’s paul j. chirik, a 2016 award recipient. “striking features common among many of the winners is that green chemistry often results in an improved product or a cost savings, demonstrating that environmentally responsible science does not have to come with reduced performance or added cost.”, the following vignettes tell the stories of this year’s award-winning technologies., heat-and-serve thermal paper bypasses bisphenol a.

Chemists regularly come up with great products that are later discovered to have a shortcoming. With green chemistry principles as a guide, that’s an opportunity to go back to the drawing board and find a game-changing solution. Thermal paper used for printing cash register receipts, tickets, and labels is one such success story.

In traditional thermal paper, a colorless dye and a chemical developer such as bisphenol A are coated on the paper. When heated, BPA interacts with and protonates the dye to alter the structure, switching its color from white to black. However, concerns over the estrogen-mimicking properties of bisphenols have led chemists to replace them where possible to reduce retail worker and consumer exposures.

Dow Chemical and papermaker Koehler jointly landed the Designing Greener Chemicals Award for a technology that uses a polymer coating on paper to create fade-resistant thermal-printed images stemming from the altered refractive index of the coating. This physical process replaces the chemicals in the thermal paper.

The coating is made from an opaque layer containing Dow’s Ropaque styrene acrylic resin hollow spheres and a colored layer containing a permanent pigment, such as carbon black. Dow originally developed Ropaque as a pigment to replace more expensive titanium dioxide in paint formulations, and it also has come to be used in personal care products such as sunscreens. The spheres function as air voids that scatter light. This is the same effect that makes polystyrene foam and clouds appear white.

When a thermal printhead heats the paper, the air voids collapse and become transparent, revealing the color below without the need for a chemical developer. The added benefit of the new technology is that it works using existing thermal printers. The paper has been tested in a few stores so far and will be in commercial use this year.

Ropaque-based thermal paper “is an amazing innovation,” says A. N. Sreeram, Dow’s chief technology officer. “It takes an entirely new approach by eliminating chemical developers for improved safety, yet it still works in existing equipment. This technology really demonstrates the passion of our people to deliver inventive solutions to customer problems.”

“It’s a classic approach to simply replace molecules that are discovered to have adverse environmental or health effects, such as BPA,” says chemistry professor Audrey Moores of McGill University, an expert in green chemistry who focuses on recyclable nanoparticle catalysts. “However, the replacement can be just as bad. To escape this unproductive cycle, a more innovative approach is to reinvent the material from scratch so that it achieves the same function with less chemistry. This is exactly what Dow and Koehler have done. This is a true example of a material made to be ‘benign by design’ by thinking outside the box.”

The rare-earth metals are a group of 17 elements, lanthanum to lutetium along with scandium and yttrium, whose properties make them useful and often irreplaceable in electronics and lighting applications. Manufacturers often blend rare earths to tune the properties of the needed materials, such as permanent magnets for electronics and phosphors for lighting. But the chemical properties of rare-earth cations are similar, making separating them for recycling difficult.

Ligand separates rare earths for recycling

Eric J. Schelter’s group at the University of Pennsylvania got the nod for this year’s Academic Award for developing a simplified process that uses tailored nitroxide ligands to separate mixtures of rare-earth metals for recycling. The approach is expected to reduce energy use and waste generated during recycling of rare-earth metals from cell phones, magnets used in motors, and other products to help minimize new rare-earth mining—a costly, energy-intensive, and waste-generating process.

The ligand that the researchers designed, tris(2- tert -butylhydroxylaminato)benzylamine, or TriNOx, forms a size-sensitive, tripod-shaped aperture when it binds the metals. For larger diameter metals, a dimeric complex forms. For smaller diameter metals, a monomeric complex forms. For example, neodymium-based permanent magnets (Nd 2 Fe 14 B) contain some dysprosium to improve thermal performance. When TriNOx is added to solutions containing salts of the two metals, neodymium—the larger metal—forms a soluble dimeric complex, whereas dysprosium forms a monomeric complex that precipitates. Schelter’s group developed a complete recycling process to recover the two metals by filtration and reuse the ligand.

The team has also shown the ligand’s separation prowess for phosphor materials that include mixtures of yttrium and europium. Overall, the UPenn researchers have demonstrated the ability to separate more than 50 pairwise combinations of rare earths. The new approach offers an easier, less expensive alternative to redox chemistry, acid-leaching processes, and ionic liquid extraction currently being used and explored for recycling rare earths.

“Our method demonstrates that rare-earth mixtures can be purified by applying the principles of coordination chemistry,” Schelter says. “The work is still in the early stages, but the results are important because they demonstrate a new type of targeted metal separation specifically for recycling.”

“Rare-earth recycling has enormous potential benefits,” says chemistry professor Audrey Moores of McGill University, an expert in green chemistry who focuses on recyclable nanoparticle catalysts. “This discovery has a major impact on greener processes at multiple levels: It means less mining pollution, less e-waste, and better access to key elements for cleantech innovation.”

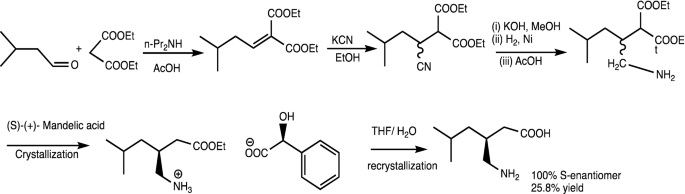

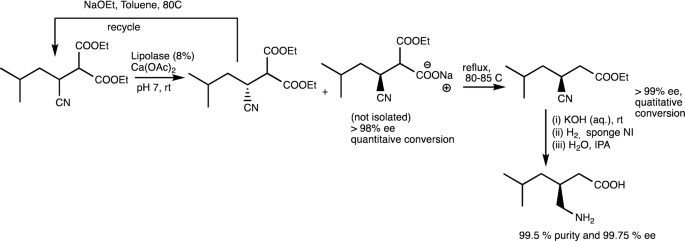

Peptides have gained increased interest as therapeutic drugs over the past three decades because of their high specificity and safety compared with small-molecule drugs. They are becoming the treatment of choice for some cancers, enzyme and protein disorders, and degenerative and infectious diseases. Their pharmaceutical rise has prompted companies to look at more efficient manufacturing processes for peptide-based therapeutics to reduce the environmental impact and production costs.

Chipping away at the cost of peptide manufacturing

Biotechnology firm Amgen and peptide manufacturer Bachem teamed up to receive the Greener Reaction Conditions Award for improving the manufacturing process for etelcalcetide , the active ingredient in Parsabiv, a calcium inhibitor to help control overactivity of the thyroid gland in patients with kidney disease. The new process produces more peptide in less time while drastically cutting solvent and water use and reducing production costs.

“We’re proud of this award that recognizes how scientific innovation can improve our manufacturing technologies and lead to a green and more efficient process,” says Margaret Faul, Amgen’s executive director of process development. “This new process for solid-phase synthesis leveraged the different areas of expertise across Amgen and Bachem.”

Peptides are synthesized stepwise by coupling the carboxyl group, or C-terminus, of one amino acid to the amino group, or N-terminus, of another using liquid-phase or solid-phase synthesis. In solid-phase synthesis, which is now most common, the peptide backbone is assembled one amino acid at a time while attached to resin beads, which requires washing away residual reagents at each step. Producing 1 kg of peptide typically requires several metric tons of solvent and thousands of liters of water, according to the companies’ environmental analysis.

As Amgen anticipated etelcalcetide approval, Faul and her colleagues realized the original production process would be problematic for commercial-scale manufacturing, given the amount of materials needed and the waste generated. Amgen and Bachem redesigned the process to bypass one of the five production stages and optimize the remaining four.

The process development team, led by Amgen’s Sheng Cui, eliminated an ion-exchange column process requiring more than 3 L of water for every gram of drug and reduced the number of energy-intensive freeze-drying (lyophilization) purifications from 13 per batch of peptides to one. The results are a fivefold increase in manufacturing capacity while cutting manufacturing time by more than half and reducing solvent use by 71%. Overall, the new process cut manufacturing costs by 76%.

“This work constitutes a textbook example of how green chemistry and engineering improvements for a process can result in both clear and tangible environment benefits while making the costs of the process more favorable,” says chemistry professor Audrey Moores of McGill University, an expert in green chemistry who focuses on recyclable nanoparticle catalysts. “The green improvements to all stages of the manufacture of the active species essentially made it possible for the companies to launch this molecule. This is quite remarkable and shows that green chemistry and economics often operate hand in hand.”

As electrical grids become larger and more complex, supplemental energy storage using batteries and other technologies is needed to smooth out supply and demand peaks and troughs. Lithium-ion batteries have the energy density needed for this task, but they are capable of operating for only a couple of hours at a time and have a limited lifetime. In addition, lithium-ion batteries have notable challenges with thermal runaway of their layered materials and with flammability of their organic-based electrolyte.

Better batteries for the electrical grid

Redox flow batteries are a promising technology for long-duration applications for electrical grids and to manage power for commercial and industrial facilities. But scientists and engineers must improve flow battery efficiency and reduce their size and cost.

UniEnergy Technologies , in collaboration with Pacific Northwest National Laboratory (PNNL), garnered the Small Business Award for its design of a next-generation vanadium redox flow battery system that takes a giant step in that direction. The company’s megawatt-scale Uni.System has double the energy density of previous vanadium redox flow batteries even though it’s one-fifth the size and requires smaller amounts of chemicals.

Instead of storing electrical energy in solid electrodes, as most batteries do, a redox flow battery stores chemical energy in a pair of electrolyte solutions. The conversion from electrical energy to chemical energy (charging) and vice versa (discharging) occurs within the flow battery’s electrodes as the electrolytes circulate through the cell.

UniEnergy’s vanadium redox flow battery chemistry originated at PNNL. Liyu Li and Gary Yang, two members of PNNL’s energy storage team, founded UniEnergy, licensed the technology, and recruited a technical and business team. The key innovation for the new battery was replacing a sulfate-based electrolyte with a chloride-based electrolyte.

This seemingly simple switch improves the stability of the battery to increase its lifetime and enables it to function with a broader operating temperature range compared with the prior generation, so it can be deployed just about anywhere, even in extreme hot or cold climate zones. Furthermore, the electrolyte storage tanks act as a heat-exchange system, so the battery stays cool—no thermal runaway. And the aqueous electrolyte is nonflammable and recyclable.

The previous generation of vanadium redox flow batteries took up the space of a tennis court. UniEnergy designed the new battery to fit in standard 20-foot shipping containers, which reduces the amount of vanadium and construction materials needed. The Uni.System is now being used at multiple sites in the U.S. and Europe.

“Advances in chemistry have made this flow battery competitive with lithium-ion batteries for long-duration applications,” says Imre Gyuk, director of energy storage research at the Department of Energy, which funded the original battery development.

“This change in electrolyte chemistry has allowed these inventors to greatly improve the stability of flow batteries to reach unlimited cycles without flammability,” says chemistry professor Audrey Moores of McGill University, an expert in green chemistry who focuses on recyclable nanoparticle catalysts. “The discovery is an example of fundamental electrochemistry research leading to the design of better materials that are necessary to support the transition to renewable energy.”

When pharmaceutical companies have a promising drug candidate that is ready to move forward for clinical testing, process chemists are called upon to develop a synthetic pathway to scale up production of the compound. Often the new synthesis is done in a hurry because time is of the essence to get the drug into the clinic. When the company is ready to move the drug forward for approval, process chemists revisit the synthesis, looking for ways to improve it for manufacturing.

Process chemists find a greener path to antiviral drug

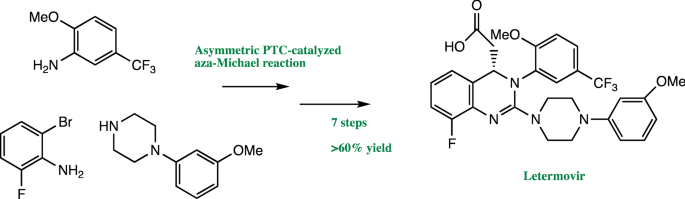

When Merck process chemists investigated ways to streamline the synthesis of the antiviral drug letermovir, they discovered a number of new asymmetric reactions to reduce its environmental footprint and published their initial success story ( Org. Process Res. Dev. 2016, DOI: 10.1021/acs.oprd.6b00076 ). The team’s revised synthesis could have been used as the manufacturing route. However, the new alkaloid-based quaternary ammonium phase-transfer catalyst for the key asymmetric cyclization step was ultimately not recyclable. The team went back to the screening phase and discovered a more stable and effective, fully recyclable catalyst. Merck’s overall achievement has been recognized with this year’s Greener Synthetic Pathways Award.

Letermovir is currently awaiting approval for fighting human cytomegalovirus infections in organ transplant recipients, a condition that currently doesn’t have an effective drug. The award-winning synthesis reduces the process mass intensity for making letermovir, a sustainability measure of raw materials, solvents, and water used per amount of product made, by 73% compared with the original synthesis.

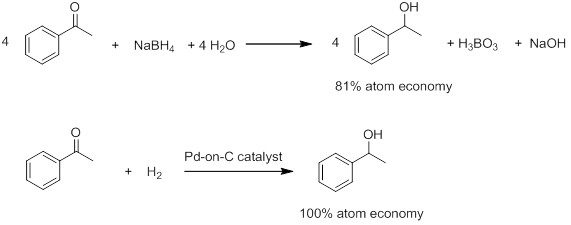

“We’ve had a long-standing commitment to green and sustainable processes,” says Kevin R. Campos, who leads Merck’s process chemistry group. “We are proud of the fact that nearly every atom of every reagent in the commercial process for letermovir is either incorporated into the molecule or recycled—it’s highly atom-economical.”

“Our ultimate goal is ‘zero waste’ pharmaceutical manufacturing,” adds Merck process chemist Guy R. Humphrey, who helped lead the discovery team and development of the manufacturing route.

The original synthesis centered on a procedure involving a guanidine intermediate to obtain the desired letermovir stereoisomer, which had limited the overall product yield. Other inefficiencies were the use of a large amount of palladium catalyst to prepare an earlier intermediate in the synthesis pathway, as well as the use of nine different solvents, including hazardous dioxane and chlorobenzene.

Using high-throughput screening tools, the Merck team explored four alternative asymmetric reactions with hundreds of potential catalysts and reaction conditions. The researchers tested thousands of combinations on a submilligram scale to find the optimal replacement for the procedure to isolate the needed stereoisomer. The outcome was the discovery of a new asymmetric aza-Michael cyclization using a hydrogen-bonding chiral bistriflamide organocatalyst.

The combined improvements increased letermovir’s overall yield by more than 60% and reduced raw material costs by 93%. The researchers estimate that the optimized process will eliminate more than 15,000 metric tons of waste over the lifetime of letermovir.

“Merck really showcases production optimization of letermovir in the context of its ‘zero waste’ goal,” says chemistry professor Audrey Moores of McGill University, an expert in green chemistry who focuses on recyclable nanoparticle catalysts. “Their strategy combining innovative organic synthesis methodology with life-cycle analysis results in an impressive reduction of the carbon footprint and water usage with a direct economic impact.”

Sign up for C&EN's must-read weekly newsletter

Contact us to opt out anytime

You might also like...

- Share on Facebook

- Share on Linkedin

- Share on Reddit

This article has been sent to the following recipient:

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter

The power is now in your (nitrile gloved) hands

Sign up for a free account to get more articles. or choose the acs option that’s right for you..

Already have an ACS ID? Log in

Create a free account To read 6 articles each month from

Join acs to get even more access to.

- ABOUT GREEN CHEMISTRY

- WHY TO USE THE GREEN CHEMISTRY TOOLKIT?

- WHO CAN USE THE GREEN CHEMISTRY TOOLKIT?

- INTRODUCTION

- ONE-DAY TRAINING

- FOUR-DAYS TRAINING

- CASE STUDIES

- LIST OF TECHNOLOGIES

- USEFUL LINKS

Home Case Studies

Case Studies

Selected case studies illustrate how the Green Chemistry approach can be applied in different companies and how it contributes to reduce the consumption of hazardous chemicals and enhance their economic and environmental performance

green chemistry, green chemistry toolkit, green chemistry toolkit UN, green chem, current research in green and sustainable chemistry, sustainable chemistry, green chemistry examples, green chemistry is, green analytical chemistry, green chemistry rsc, green chemical engineering, need of green chemistry, examples of green chemistry in everyday life, green chemistry meaning, green chemicals list, the green chemist, green chemistry notes, green chemistry in sustainable development, green chemistry in pharmaceutical industry, green chemical company, trends in green chemistry, green chemistry companies, green sustainable chemistry, green chemistry and technology, green and sustainable chemistry, green chemistry experiments, green chemistry, green chemistry toolkit, green chemistry toolkit UN, green chem, current research in green and sustainable chemistry, sustainable chemistry, green chemistry examples, green chemistry is, green analytical chemistry, green chemistry rsc, green chemical engineering, need of green chemistry, examples of green chemistry in everyday life, green chemistry meaning, green chemicals list, the green chemist, green chemistry notes, green chemistry in sustainable development, green chemistry in pharmaceutical industry, green chemical company, trends in green chemistry, green chemistry companies, green sustainable chemistry, green chemistry and technology, green and sustainable chemistry, green chemistry experiments

Ionic liquids as potential green solvents for purification of manufacturing waste-water Chemical: Ionic liquids as a green solvent Chemicals replaced: Conventional toxic organic solvents Process: Purification of manufacturing waste-water Country: Serbia

Change in the formulation of solvents derived from petroleum for d-limonene considered green solvent in several polikem products Chemical: D – limonene as a green solvent Chemicals replaced: Petroleum-derived solvents Process: Cleaning/degreasing of brakes, motors, and other metal parts Country: Colombia

Production of ethylene from bio-ethanol Chemical: Bio-Ethanol – organic waste as a green raw material Chemicals replaced: Natural gas or petroleum products Process: Utilization of waste / production of chemical product (ethylene) Country: Egypt

Water-base application for wood coating Chemical: Water based coatings Chemicals replaced: Solvent-based coatings Process: Wood coating Country: Sri Lanka

Watch the videos Business Case

This can be useful List of technologies

1.1 Green Chemistry: First, Do No Harm

1.1.1 definition of green chemistry, 1.1.2 principles of green chemistry, 1.1.3 economic driving force, 1.2 better living through chemistry, 1.2.1 predicting harm: evolution of refrigerants, 1.3 environmental pollution, 1.3.1 ddt and silent spring, 1.3.2 times beach and love canal super fund sites, 1.4 risk is a function of hazard and exposure, 1.4.1 hazards: union carbide explosion in bhopal, india, 1.5 toxicology and environmental chemistry, 1.6 life cycle analysis, 1.7 case study: polylactic acid (pla) (natureworks ® ), 1.8 resources: the scientific literature, 1.8.1 databases, 1.8.2 journals, 1.9 implementation of green chemistry, 1.10 summary, 1.11 problems: prevent waste, problem 1.1, problem 1.2, problem 1.3, problem 1.4, problem 1.5, problem 1.6, problem 1.7, problem 1.8, problem 1.9, 1: prevent waste.

- Published: 03 Dec 2019

- Product Type: Textbooks

- Open the Chapter PDF for in another window

- Get permissions

- Cite Icon Cite

Green Chemistry: Principles and Case Studies, The Royal Society of Chemistry, 2019, pp. 1-22.

Download citation file:

- Ris (Zotero)

- Reference Manager

Green chemistry is a conscious change in the way we do chemistry—to do no harm. Chemistry is a powerful tool to improve the quality of our lives. We all reap the benefits of chemists who have improved the quality of modern life. Tragic experiences, such as Silent Spring, Times Beach, Love Canal, and Bhopal, have proven that it is nearly impossible to eliminate exposure to hazardous chemicals that have already been used in the production of these beneficial modern products. So green chemistry seeks to eliminate risk by avoiding the use and production of hazardous chemicals in the first place. Of great use to green chemistry are the tools of toxicology, environmental chemistry, life cycle analysis, and of course, the scientific literature that encompasses all of these areas. Cargill Dow exemplified the use of life cycle analysis in the production of NatureWorks ® polylactic acid from corn. Implementing green chemistry is a question of public policy: should governments attempt to force the change, or will market forces make it happen?

“Principle 1: It is better to prevent waste than to treat or clean up waste after it has been created.” 1

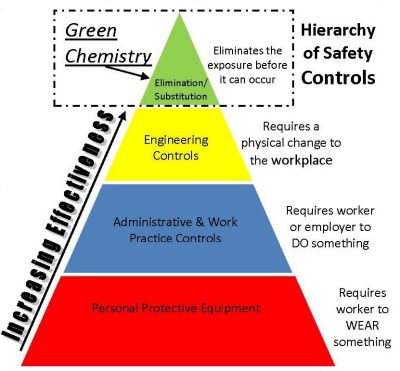

Green chemistry aspires to give us all of the wonderful products we have come to expect in our lives, without the associated pollution of the past. The job of green chemists is to eliminate hazards completely from our processes and products, so that no accidental release or exposure would be possible. That is the ideal, the lofty goal we aspire to, but the reality is one of more gradual shift and compromise, tempered by economics and regulations. The Green Chemistry Institute was founded in 1995, the same year the US Presidential Green Chemistry Challenge (PGCC) Awards were established by the US Environmental Protection Agency (EPA) under President Bill Clinton. These awards have now inspired industrial and academic chemists to invent new products and processes that are “benign by design,” or sustainable without polluting the environment.

Chemists have serious responsibilities in our profession. Whether a chemist or a company chooses to ignore the consequences of their chosen chemicals and methods, or to take great pains to produce the best products in the least polluting way that one can imagine, chemistry has consequences. Green chemistry holds that each chemist, each company, is responsible for preventing accidents and pollution, and for using the least amount of resources necessary. Green chemistry has as its core value, a chemist's version of the Hippocratic Oath, “First, Do No Harm.” 2 This injunction is particularly apt in the case of chemistry, where the products of our labor may last for years, or even centuries, for better or for worse.

“Green chemistry is the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances.” †

A course in Green Chemistry might just as well be called Industrial Chemistry, because green chemistry is about making commercial products by clean and efficient methods. In many ways, industry is leading the way in making greener products. Half of the PGCC awards have been to industry. PGCC awards also go to academic chemists with a strong desire that their greener process or product find application in society, so much so that they often start a company to commercialize their chemistry. Many of the chemicals described in the case studies of this book are commodity chemicals, such as starting materials for things like plastics or dyes. Commodity chemicals are defined by the large scale of their production, and the global market for their distribution. Others are fine chemicals, made on smaller scale, but just as crucial, like medicines. Green chemistry is all about the applications, thus this book will be grounded in case studies, primarily from the US Presidential Green Chemistry Challenge (PGCC) Awards.

In 1998, Paul Anastas and John C. Warner published a seminal book, Green Chemistry: Theory and Practice , which established the 12 Principles of Green Chemistry as the foundation for this dramatic shift in the way we do chemistry. 1 The 12 Principles fall into three general categories: (1) use and produce no toxic chemicals, (2) minimize the use of chemical and energy resources, and (3) prevent accidents. The chapters in this book are organized by Principle, but many of the case studies use several of the principles to achieve their goals. These illustrative case studies are designed to inspire the student to find new ways to apply the principles in their future work.

One of the cool things about green chemistry is that greener processes and products are also typically more economical, with renewable feedstocks, fewer steps, lower energy costs, and lower hazardous waste disposal costs.

In 2001, Shaw Industries was bought by Berkshire-Hathaway Inc. headed by Warren Buffett. Shaw developed EcoWorx carpet tiles that were completely recyclable back into carpeting. 4 A number of economic advantages propelled EcoWorx to a market share of 80% of the carpet sold in their product line. The feedstocks were old carpet tiles sent back for remanufacturing. The carpet tiles were made from lighter materials that required less energy in manufacturing and shipping. The EcoWorx product line is highly successful.

Carpet tiles originated with Interface, Inc., whose owner, Ray Anderson said, “Sustainability is proving to be incredibly good for business. What began as the right thing to do quickly became the smart thing to do. Sustainability doesn't cost, it pays.” 5

Unfortunately, we are still in a time of cheap fossil feedstocks—petroleum and coal, and this can doom a greener process. For example, Dupont developed a new method for breaking down polyethylene terephthalate (PET) into the two monomers that could then be repolymerized into virgin PET. They built a pilot plant in North Carolina in 1996 that produced 100 million pounds of PET per year, but a drop in oil prices led to the plant closure and dismantling in 2000. There may come a day when oil prices rise, and recycling PET could again become cost competitive.

There is no doubt that the modern world has benefited enormously from the efforts of chemists, without which we would not have most medicines, fuels, computers, in short, the stuff of modern life. In 1935, Walter Carothers invented a nearly indestructible fabric, nylon. The same year, Dupont asserted in an advertising slogan, “Better Things and Better Living…through Chemistry,” which was later co-opted and shortened to “Better Living Through Chemistry.” One of the earliest organic synthesis industries, the German synthetic color dye industry, spawned the first medicinal chemistry program. The first antibiotic, sulfanilamide (first a red dye), 6 saved countless lives, and was forerunner to the whole class of antibiotic drugs. We are now on the cusp of individualized medicine, in which each patient's unique physiology and disease progression are considered when designing and prescribing medical treatment. The tricky part will be whether we can, at the same time, avoid side effects and the production of toxic pollutants in the process of converting to individualized medicine.

We have to know what the potential harm might be before we can know that we should avoid it. In the early 1900s, refrigerators that used ammonia as the coolant were used commercially, but the acute toxicity of ammonia gas prevented widespread use in homes. The solution came when chemists at General Motors developed Freon ( Figure 1.1 ), patented in 1928 as a refrigerant, which was non-flammable and of very low toxicity. Perhaps this could be considered an early attempt at green chemistry. Fifty years later, chemists Frank S. Rowland and Mario J. Molina, discovered that Freon could destroy the ozone layer of the stratosphere that protects living things from UV radiation. Together with Paul Crutzen, they were awarded the Nobel Prize in Chemistry in 1995 for their work on ozone depletion. The chemists at General Motors who invented CFCs did not anticipate, nor could they even have been expected to anticipate, any larger problems with CFCs.

Refrigerants, L to R: Freon, (HFC)-134a, and (HFO)-1234yf.

The next step in replacements for CFCs contained only fluorine, carbon, and hydrogen, primarily hydrofluorocarbon (HFC)-134a, 1,1,1,2-tetrafluoroethane, which does not destroy the ozone layer ( Figure 1.1 ). Unfortunately, the saturated HFCs are potent greenhouse gases. 7 HFC-134a has a 100-year global warming potential (GWP) that is equivalent to 1430 times that of CO 2 . 8 Currently, hydrofluoroolefin (HFO)-1234yf (2,3,3,3,-tetrafluoropropene) is considered an efficient and safe refrigerant with a 100-year GWP less than 1 ( Figure 1.1 ). US and Japanese automakers are switching to HFO-1234yf, however Mercedes-Benz engineers in Germany found that it ignited on a hot engine when mixed with the compressor oil necessary for air conditioning. 9 Highly corrosive HF gas, given off in the fire, etched the windshield in their test. 9 Under ordinary release conditions, HFO-1234yf degrades by oxidation to trifluoroacetic acid (TFA), 10 a strong, toxic acid for which the environmental safety has not yet been fully assessed. 11

The most benign refrigerant under development is CO 2 . 12 CO 2 has a GWP of 1 by definition, well below the European Union requirement for refrigerants to be below a GWP of 150. CO 2 is cheap, abundant, non-toxic, and all natural; it is not subject to government regulation and can be released to the atmosphere requiring no special recovery methods. Any CO 2 used in refrigeration would either be withdrawn from the atmosphere or recovered from burning fossil fuel for energy. One problem with CO 2 is that it operates as a refrigerant best under transcritical conditions, above the critical pressure of 73 atm. 13 This is essentially an engineering design problem, requiring new systems with stronger containers and special valves. There are also engineering advantages. The volumetric refrigeration capacity is higher for CO 2 , so units can be smaller. 13 The compression ratio is about half that of HFC compressors, increasing the efficiency. 13 The problems have been solved for stationary refrigeration, and German automakers are working on a solution for vehicles. 14

We have yet to discover a truly benign, efficient substitute for HFCs. This illustrates the difficulty of finding truly green chemical solutions for significant societal needs. No one wants to go back to the days of smelly, moldy iceboxes, or worse yet, no refrigeration or air conditioning at all. Replacing HFCs remains a significant opportunity for green chemists.

The chemists who developed Freon, indeed all of us, were unaware of stratospheric ozone destruction by CFCs. Our collective ignorance leads one to wonder if there are other types of environmental or biological harmful effects that we do not yet know, cannot predict, or have missed in the literature. It is wise for chemists to pay attention to the work of toxicologists and environmental chemists. Whatever type of harm is known, we should take care to avoid in our work.

Most people lack interest in, or feel incapable of comprehending, the chemistry used to make the products they use. We just want our things to function well. We want durable goods, like a refrigerator, a house, or a car, to last a long time and to still function. We want a product that is supposed to be temporary, like a plastic bag, to go away; we want to drop it in the trash and have it disappear. And this is where chemists have succeeded heroically, and also failed miserably. Our work is a work in progress.

What most people do care about is a clean environment, at a minimum in their own backyard—hence the term “not in my back yard” or NIMBY, that refers, often derogatively, to people fighting against contamination of their home or community environment. We want clean air to breathe, clean water to drink, clean food to eat, and clean places to live, play and work. The connection between the chemistry used to make products and a clean environment is obscure to many, though it has become more mainstream since 1970, when the US Clean Air Act was passed. 15 The US Federal Water Pollution Control Act Amendments of 1972, now known as the Clean Water Act of 1977, 16 did much the same for water pollution consciousness.

The environmental consciousness of the modern era has been attributed to publication in 1962 of the book, Silent Spring by Rachel Carson. 17,18 In this moving and superbly written account of the dramatic deformities and stillbirths of birds caused by the pesticide 2,2- p,p ′ - dichlorodiphenyl-1,1,1-trichloroethane (DDT, Figure 1.2 ), Carson was first to observe endocrine disruption in birds. It was Carson who first pointed the finger at ourselves, “…no enemy action had silenced the rebirth of new life in this stricken world. The people had done it themselves.” 18 This new attitude found its way into popular culture with Walt Kelly's Pogo comic strip on the newly founded Earth Day in 1971 ( Figure 1.3 ).

The structure of 2,2- p,p ′ - dichlorodiphenyl-1,1,1-trichloroethane (DDT).

We have met the enemy, and he is us. Pogo comic strip by Walt Kelly published on Earth Day, April 22, 1971. Copyright Okefenokee Glee & Perloo, Inc. Used by permission. Contact [email protected].

The environmental movement had a big job cut out for it. Although toxicology is an ancient science, the twist was that chemical manufacturing was producing and selling novel synthetic or “man-made” substances for which there were no health effects data, and none were required by law. Two events galvanized a public now attuned to environmental issues. In 1972, Russell Martin Bliss sprayed waste oil contaminated with dioxin (2,3,7,8-tetrachlorodibenzodioxin, Figure 1.4 ) in Times Beach, Missouri. The dioxin and trichlorophenol caused many birds and horses to die immediately, and caused severe health effects to the people living in the town. Dioxins are among the most potent toxins known.

![case study on green chemistry Structure of the most common dioxin: 2,3,7,8-tetrachlorodibenzo[b,e][1,4]dioxin.19](https://rsc.silverchair-cdn.com/rsc/content_public/books/871/parts/bk9781788017985-00001/5/m_bk9781788017985-00001-f4.jpeg?Expires=1728187174&Signature=DUnFhcvSJiKUTnk69ic3SwNz8beCC0yr2vxLkQckXG7Cn1mxZH~8rkAwIBR4UUJBJGlkj8TC5K0W6IogV2f6zJOZKenbS6j~9P1aoODG-8b12BCijxcUK1TP0DvAUIPLBlIZDhszXKevfagz70eKyNQBTKghxR57-ErEtWsrgEtxOaNJm6~-6CqSXUyKHIg9ygO1OgwuhPnlXRwL9fFhdgAbevQTtFleNnMdrDL4joP6~aacoAOIZVnkU4lkj3MWlh5fSuC44~Pr2GDfcKPUiCAIEBnX-i8D6hk3ORR6Bup7c18i5EbLVJ-LK0ODs0-di-hwX024mHhQ94Qkx5WSOQ__&Key-Pair-Id=APKAIE5G5CRDK6RD3PGA)

Structure of the most common dioxin: 2,3,7,8-tetrachlorodibenzo[b,e][1,4]dioxin. 19

There is still much concern about the formation of dioxins in municipal waste incinerators and paper bleaching. In order to completely destroy dioxins during incineration, three conditions are necessary: (1) high combustion temperature, (2) adequate combustion time, and (3) high combustion turbulence. 19 Dioxins form as flue gases are cooling during emissions or flue gas filtration, so incinerator design is vital, especially when chlorine-containing compounds are being incinerated. 19

In 1977, severe health effects due to toxins leaking from the Hooker Chemical Co. waste site at Love Canal, NY came to light by the efforts of two investigative newspaper reporters for the Niagara Falls Gazette, David Pollak and David Russell. The result was the Super Fund, or Comprehensive Environmental Response, Compensation and Liability Act of 1980, which is used to this day to clean up hazardous waste sites.

The sad lesson of Love Canal is that burial of toxic waste in landfills is no guarantee of safety on a human history time scale, or in the case of nuclear waste, on a geological time scale. Thus, the primary goal of green chemistry is neither to use nor produce toxic substances in the first place.

Green chemistry differs from environmental chemistry in that we seek to avoid using and creating chemical products that are in any way hazardous. In my first job out of college, I worked with and synthesized very hazardous substances—radioactive carcinogens—that were used in environmental and biological studies of pollution. Our primary goal was, understandably, to protect ourselves with fume hoods, double-door entries, rubber shoe covers, white paper “zoot” suits worn over our clothes, double gloves, safety glasses, and weekly urine and lab monitoring. This approach epitomizes the exposure-avoidance model of safety that was in vogue in 20th century industry, which is still used in most chemistry laboratories. What we did not much consider was that the hazardous fumes were going out the hood into the community, or the barrels of radioactive, carcinogenic, and flammable waste that were sealed and put into landfills. (Explosives were taken out into a field and shot with a rifle to detonate and inactivate them.) Little consideration was given to what happens when those barrels corrode and begin to leak into the environment, such as what happened at Love Canal in Niagara Falls, NY in 1953. After many other infamous chemical spills, releases and exposures later, including the horrific explosion in Bhopal, India, and the spraying of dirt roads and horse arenas with dioxin-contaminated oil in Times Beach, Missouri (unsettlingly close to my home town), we are finally wising up.

Anastas and Warner set out the principle of risk as an equation. 1 If either hazard or exposure is zero, then zero risk is involved. Zero risk, that is, in a perfect world.

Their point was that we have historically aimed to eliminate risk by eliminating exposure, through the use of barriers, such as gloves, laboratory coats, fume hoods, blast shields, double-walled reactors, double-hulled petroleum tankers, etc. The sad truth is that barriers break, gloves tear, fume hoods emit toxins into the local air, ships are breached, and we are all eventually exposed to toxins that begin leaking from hazardous waste sites once a steel drum begins to rust, like at Love Canal.

Many chemists have a sense of pride in their ability to handle hazardous chemicals safely. I am one of these—I have used 3 H and 14 C (both radioactive), Hg, HF, and many other extremely hazardous chemicals in my work over the years, and I am proud of my skills in their safe handling. There are many chemicals I would rather not ever touch. Derek Lowe, a medicinal chemist well known for his blog “In the Pipeline,” has an entertaining, long, and growing list of “Things I Won't Work With.” 20 A better way, the ideal of green chemistry, is to use non-toxic, non-flammable, and non-explosive chemicals to eliminate the hazard part of the risk equation entirely, so that exposure is no longer an issue, and risk ideally becomes zero.

We will see that green chemists sometimes compromise. In a case study on the BHC synthesis of ibuprofen in Chapter 2, extremely dangerous HF is used as a Lewis acid to replace AlCl 3 in a Friedel–Crafts reaction, which eliminates tons of hazardous waste (AlCl 3 · xH 2 O). The HF is easily recycled because of its low boiling point. This is a compromise because the reaction is more atom economical. Yet HF was the first chemical Derek Lowe posted on his “Things I Won't Work With” blog, a good starting list of chemicals to avoid for prevention.

Toxicity is not the only hazard that green chemistry seeks to avoid. Highly reactive, compressed gas, explosive, flammable, corrosive, strongly acidic, basic, oxidizing or reducing chemicals are also hazard concerns. On December 3, 1984, a terrible explosion at a Union Carbide India plant resulted in the death of 5200 people, and thousands of others were permanently or partially injured in Bhopal, India. 21 A storage unit that contained 42 tons of methyl isocyanate (MIC) had water leak into it through a faulty valve, initiating an exothermic reaction. The pressure built up and the tank exploded, releasing MIC along with other reaction products. MIC is flammable, reactive with water, and very toxic to the respiratory system. 22 MIC has a boiling point of just 39 °C, so that it becomes a gas with minimal temperature elevation. MIC is extremely hazardous—the cause of most of these deaths was pulmonary edema, or excess fluid in the lungs. 23 One of the lessons from Bhopal is that highly reactive chemicals, such as MIC, should be avoided in chemical synthesis if at all possible.

In order to design better processes and products, chemists need to know what is hazardous, and why, in order to avoid it. Toxicology is the discipline that studies the biological effects of toxic chemicals, both the qualitative (severity), and quantitative (potency) aspects of toxicity, as well as the biological mechanism of action. We will see that there are ways to avoid toxicity by design in Chapter 4.

Environmental chemistry is quite distinct from green chemistry, yet environmental chemistry is a critical partner in ensuring that chemistry becomes sustainable, that all chemistry becomes green chemistry. Wikipedia says, “Environmental chemistry can be defined as the study of the sources, reactions, transport, effects, and fates of chemical species in the air, soil, and water environments.” 24 Since all matter is chemical, we should be more specific and say that environmental chemistry is the study of synthetic or mined pollutants in the environment. There are other types of pollution, such as soil loss due to agriculture or construction, but this is typically not the domain of chemists.

Environmental chemists have been analyzing ever-lower concentrations of toxic and hazardous substances in a wide array of environmental and biological samples. For example, three years after the initial dioxin spraying, and after 18 inches of topsoil were removed, soil samples at the Shenandoah Stables in Times Beach were found to contain 30 ppm of dioxin, which is a very high level of this potent toxin. 25 Now, environmental chemists routinely find parts-per-trillion (ppt), equivalent to picomolar (10 −12 M), concentrations of dioxin. 26 This illustrates that there is no such thing as a zero concentration of a pollutant in the environment. It is a question of the detection level of an instrument for a specific substance, by a particular method, in a particular matrix.

Once the type and amount of a substance is found, environmental chemists are charged with figuring out how to clean up the mess, whether to attempt to destroy it, or to gather it up for disposal in a landfill, which of course could leak later. Environmental chemistry has the unenviable job of detecting, analyzing, and cleaning up manmade pollution.

The best tool that has emerged for pollution prevention with green chemistry is the life cycle analysis (LCA), the study of the production of a product from cradle to grave, or better yet, as McDonough and Braungart titled their book, cradle-to-cradle . 27 LCA is an extremely useful method for chemists and engineers to analyze the entire life cycle of a product.

LCA is a 21st century method for analyzing the sustainability of a product or process from the extraction, mining, or growing of a resource to the ultimate fate of the product, whether landfilled, recycled, or composted. LCA is typically both qualitative and quantitative. The new greener product is compared with products currently on the market. Sustainability is measured by the overall efficiency of the process in the use of raw materials or feedstocks, energy, greenhouse gases, water, and the output of pollution. Life cycle thus refers to the entire process to make a product, use it, and dispose of it throughout the product's useful lifetime. Greener products or processes are compared with traditional products or processes that perform the same or similar functions. Each LCA establishes the criteria to be used to assess sustainability.

The first step in an LCA is to decide what will be measured. These are frequent candidates: materials in, materials out, energy used, energy produced, water used, water released. This may sound formidable, yet it is already a necessary part of the economics of designing a chemical production plant, or the process chemistry to synthesize a medicine.

A complete LCA can sometimes deliver surprising results. Hexamethylene diamine (HMDA) is one of the two key monomers used to make nylon-6,6, which is the nylon used in our backpacks, clothing, carpet, car parts, and many others. Solvay (China) Co. discovered that production of HMDA from starch is more polluting and energy-intensive than production from petroleum ( Figure 1.5 ). 28 Although the bio-based route from sugars had greenhouse gas emission advantages over the petroleum-based route, energy-intensive drying of the hydroxymethylfurfural (HMF) intermediate increased marine and freshwater eutrophication. Growing corn and potatoes for the starch feedstock was also found to have negative environmental consequences. 28 These challenges are not insurmountable, however. Improvements in drying technology and agricultural practices could result in flipping the LCA outcome.

Life cycle analysis (LCA) of the production of HMDA from food crop starch vs. petroleum. Reproduced from ref. 28 with permission from the Royal Society of Chemistry.

An early example of a complete LCA was performed by NatureWorks ® , a subsidiary of Cargill Dow LLC, for their polymer, polylactic acid (PLA). 29 Cargill Dow has defined sustainability by a “triple bottom line approach” of economic, social and environmental sustainability. We will only be concerned with the environmental sustainability, although the social sustainability exemplifies some green chemistry principles as well. For example, under the social sustainability criterion, Cargill Dow does not allow the endocrine disrupter (Chapter 3) bis-phenol A (BPA) to be used as a plasticizer in products made with their PLA, and they do not allow PLA to be used for packaging tobacco products. 29

PLA is a biodegradable polymer derived entirely from the renewable resource cornstarch. The carbon source is thus entirely carbon dioxide and water, which plants take up to synthesize polysaccharides using energy from the sun by photosynthesis. 29 The cornstarch is enzymatically converted into natural d -glucose, also called dextrose ( Figure 1.6 ). Dextrose is then fermented at neutral pH to produce lactic acid. A pre-polymerization step is necessary to remove water before the lactic acid can be cyclized to produce the key intermediate, lactide. The lactide is then distilled in one of the higher energy-intensive steps ( Figure 1.6 ). The final step is a solvent-free ring-opening polymerization (ROP) to produce the high molecular weight PLA product with the desired properties.

NatureWorks ® process for manufacturing polylactic acid (PLA) from cornstarch. 29

Cargill Dow chose three indicators for the LCA of PLA: (1) the use of fossil energy in production, (2) net greenhouse gases produced, and (3) water use. 29 The indicators for PLA were compared with nine petrochemical-based polymer products, and cellophane, made from an older renewable feedstock, cellulose. LCA methodology is very complex, with many decisions to be made about inclusion or exclusion of data, weighting of various factors, and approximations. 29 First, the use of petroleum, both as feedstock and as the energy source in the production of plastics, was evaluated ( Figure 1.7 ). Since PLA is derived from a bio-feedstock instead of petroleum, the total amount of fossil energy used in production is less than all of the other plastics. A net use of 54 MJ kg −1 of fossil energy was for agricultural purposes in growing the corn for feedstock, for transportation, and for chemical processing, minus the embodied solar energy in the corn feedstock. With the inclusion of lactide from agricultural waste (stalks, husks and leaves, called “corn stover”) as the biomass feedstock (Bio) and wind power (WP), fossil energy use was decreased to only about 9 MJ kg −1 ( Figure 1.7 ). Improvements in process energy would also lead to a more cost competitive product. Another advantage of using corn stover is that the process would not compete with the food supply. Thus, energy efficiency improves all three components of the triple bottom line: environment, economics, and society. 29

Fossil energy requirement for some petroleum-based polymers and polylactide. The cross-hashed part of the bars represents the fossil energy used as chemical feedstock (the fossil resource to build the polymer chain). The solid part of each bar represents the gross fossil energy use for the fuels and operations supplies used to drive the production processes. PC=polycarbonate; HIPS=high impact polystyrene; GPPS=general purpose polystyrene; LDPE=low density polyethylene; PET SSP=polyethylene terephthalate, solid state polymerization (bottle grade); PP=polypropylene; PET AM=polyethylene terephthalate, amorphous (fibers and film grade); PLA1=polylactide (first generation); PLA B/WP (polylactide, biomass/wind power scenario). Reprinted and reproduced from ref. 29 with permission from Elsevier. Copyright 2003.

Solar energy warms objects on earth, think of a rock in the sun, or a parking lot. Greenhouse gases trap heat radiated from these objects in the atmosphere. The mechanism is simply absorption of electromagnetic radiation, and emission in the infrared region back into the atmosphere. Of course, some heat is radiated out to space, but the effect of higher concentrations of greenhouse gases is net global warming. Not all geographical locations will experience the same warming; northern latitudes are warming at the greatest rate of all, and the eastern US has experienced cooler temperatures, even as the western US is burning, literally. This is why we now call it climate change. The three major greenhouse gases are rated in terms of CO 2 equivalents (C-eq): CO 2 is designated 1 C-eq; CH 4 has 21 C-eq; and N 2 O has 310 C-eq. 30

Cargill Dow included these three greenhouse gases in the LCA of PLA. In this analysis, the first generation PLA1 from feed corn did not fare much better than low density polyethylene or polypropylene, but it was much better than Nylon-6,6 or Nylon-6 ( Figure 1.8 ). The production of nylon is very energy intensive as well, which illustrates the connection of greenhouse gas production to energy use ( Figure 1.7 ). Using corn stover as feedstock and wind energy in the production of PLA B/WP actually removes greenhouse gases from the atmosphere because growing corn uses CO 2 as the most basic feedstock ( Figure 1.8 ).

Contributions to global climate change for some petrochemical polymers and the two polylactide polymers. Reprinted and reproduced from ref. 29 with permission from Elsevier. Copyright 2003.

The final impact assessed in the LCA was the use of water in plastic production. Three uses of water were analyzed: irrigation water, process water, and cooling water ( Figure 1.9 ). Even though the corn feedstock requires irrigation with water to grow it, PLA is competitive with all the major commercial plastics studied, and it beats the nylons and cellophane by a substantial margin.

Gross water use by petrochemical polymers and the two PLA cases. Reprinted and reproduced from ref. 29 with permission from Elsevier. Copyright 2003.

Overall, Cargill Dow's LCA of PLA is a model for the use of LCA for other products. They found that the current production of PLA from feed corn already has a significant environmental advantage over other polymers, and that switching to corn stover feedstock and wind power represents a dramatic improvement even over the current process. Notably, Cargill Dow did not include an analysis of the pollution prevention impact of PLA, which is a compostable product, keeping more permanent polymers, such as polyethylene terephthalate (PET) and nylons out of landfills and the oceans.

As you work through this textbook, many ideas and problems will require the use of the scientific literature. Several databases and journal resources are particularly useful and complete.

The most complete database for chemical research is Scifinder . An important tool in searching databases is the use of applicable key words. Sometimes search words will need to be made more specific to narrow the range of hits, other times search words need to be made more general. For example, in 2015, a search in Scifinder using “green chemistry” as search words turned up thousands of hits; it was too broad. On one hand, “sustainable (or green) synthesis of adderall” turned up no relevant hits; it was too narrow. On the other hand, “synthesis of adderall” garnered 669 hits; it would be extremely difficult to read and assess the green merits of each synthesis. One way to get around this is to select a recent comprehensive review article, and find the most efficient synthesis described therein. To get the best result from a search—a search result of 10 to 100 hits is useful and manageable—one must try different search words, combinations of search words, chemical structures, and reactions. Searching the literature is like a video game in that persistence and experience help you find your way, gather tools, and reach your goals.

Scifinder , chemical literature, by library subscription.

PubMed , biomedical literature, free to the public.

Web of Science , multidisciplinary, by library subscription.

Green chemistry articles are increasingly published in traditional chemical journals. Specific society collections of journals, such as the American Chemical Society (ACS: pubs.acs.org) and the Royal Society of Chemistry (RSC: pubs.rsc.org), have useful search routines that are specific for the chemical literature. The “Advanced” search links are especially useful, because you can narrow your search by years, author, or journal. Specific journals devoted to green chemistry may be useful in identifying current areas of research, and finding solutions to particular problems. You can keep up to date by browsing the table of contents of these on a regular basis.

Green Chemistry , Royal Society of Chemistry, since 1999 http://pubs.rsc.org/en/journals/journalissues/gc#!recentarticles&adv , accessed July 19, 2019.

ACS Sustainable Chemistry and Engineering , American Chemical Society, since 2013 http://pubs.acs.org/journal/ascecg , accessed July 7, 2019.

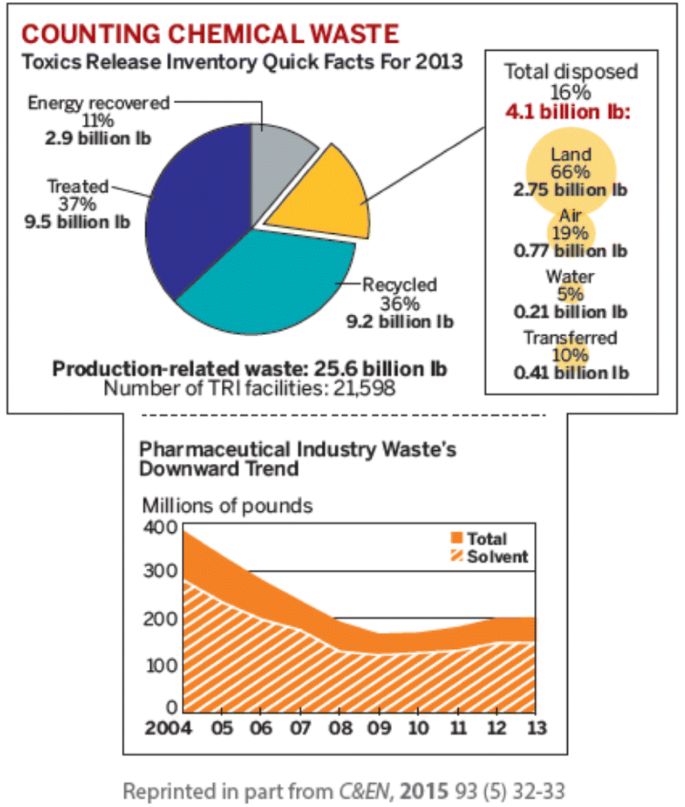

John Warner and Paul Anastas established the Principles of Green Chemistry 25 years ago. Where are we now? In 2010, Scientific American published an article that said hazardous chemicals had been reduced by about 0.5 billion kg over 15 years, but that is a drop in the bucket compared with the 33.5 billion kg per day that the US produces or imports. 31 There is still a lot of disagreement about how to make all chemistry green chemistry, that is to make the “green” in green chemistry superfluous. 31

Edward Woodhouse, a political scientist at Rensselaer Polytechnic Institute said, “One way to think about it is to ask yourself: ‘What is the purpose of government? Why isn't everything done by voluntary exchange among willing buyers and sellers?’ The answer is, of course, that a lot of important things that need doing won't be done voluntarily.” 31

“[John] Warner favors the ‘build a better mousetrap’ philosophy: Do green chemistry by making alternatives that are not only safer but effective and economical, and chemical companies will eagerly adopt them.” 31

As you learn about this new way of doing chemistry, think about whether you agree with Woodhouse, or with Warner, about the best way to achieve these goals, to make it happen.

Green chemistry is a conscious change in the way we do chemistry—to do no harm. Chemistry is a powerful tool to improve the quality of our lives. We all reap the benefits of chemists who have improved the quality of modern life. Tragic experiences, such as Silent Spring , Times Beach, Love Canal, and Bhopal, have proven that it is nearly impossible to eliminate exposure to hazardous chemicals that have already been used in the production of these beneficial modern products. So green chemistry seeks to eliminate risk by avoiding the use and production of hazardous chemicals in the first place. Of great use to green chemistry are the tools of toxicology, environmental chemistry, LCA, and of course, the scientific literature that encompasses all of these areas. Cargill Dow exemplified the use of LCA in the production of NatureWorks ® polylactic acid from corn. Implementing green chemistry is a question of public policy: should government attempt to force the change, or will market forces make it happen?

(a) Three general categories were given for the 12 Principles of Green Chemistry. List which principles fit into each of the three general categories, using the short title of each principle. Some principles may apply to more than one category.

(b) Explain your choices with as few words as possible. (Ask your instructor whether or not to use complete sentences.)

(a) Terephthalic acid (1,4-benzenedicarboxylic acid) is one of the monomers for PET. Is terephthalic acid considered a fine chemical, or a commodity chemical?

(b) Ibuprofen is an anti-inflammatory over-the-counter drug. Is Ibuprofen a fine chemical, or a commodity chemical?

DDT is used as a potent insecticide against the malaria mosquito in Africa. An article in Scientific American ( http://www.scientificamerican.com/article/ddt-use-to-combat-malaria/ ) lays out the cases for and against using DDT to control malaria.

(a) Read the article, and perhaps find others. Then choose one side or the other and write a brief argument in support.

(b) What can chemists do to prevent malaria and the use of DDT?

(c) Find one scientific paper in the chemical literature (Scifinder or Pubmed) describing a new mosquito insecticide, and assess if it would be more environmentally degradable, less toxic, or less susceptible to insect resistance. Give the full reference (Authors, Title, Journal, Year, Volume, page numbers).

DDT is considered an endocrine disrupter, a substance that interferes with the hormone chemical messenger system, often a mimic of estrogen.

(a) Draw the structure of 17β-estradiol.

(b) Next to it, redraw the structure of DDT.

(c) Circle and label the parts of the two molecules that are of similar type (polar, hydrophobic, charged), and similar arrangement in space.

(a) What are the disadvantages of choosing CO 2 as a refrigerant?

(b) What are the disadvantages of choosing N 2 O as a refrigerant?

(a) Draw the balanced reaction of methyl isocyanate (MIC) with excess water.

(b) What are the physical forms of the products?

(c) Why did the MIC tank in Bhopal explode when water leaked into it?

(a) Dioxin can be destroyed by incineration. What are the three criteria for achieving complete combustion of dioxins?

(b) Is this environmental or green chemistry? Explain briefly.

(c) Terrence Collins invented a catalyst that can be used to accelerate paper bleaching by hydrogen peroxide and avoids the formation of dioxins. Is this environmental or green chemistry? Explain briefly.

Use PubMed and Scifinder to search for “paper bleaching with hydrogen peroxide” and “health effects of dioxin.”

(a) How many hits do you get for each search term in each of the two databases?

(b) Is one database better than the other for certain topics?

(a) Draw a curved arrow mechanism for the ring-opening polymerization (ROP) of lactide into PLA initiated by H 2 O.

(b) Is this a step-growth or a chain-growth polymerization? (Hint: Look up the criteria for step-growth and chain-growth polymerization.)

(c) Why do you think the lactide intermediate must be distilled before the ROP?

From ref. 3 . Copyright © 2017 Yale University. All rights reserved.

- Campaigning and outreach

- News and events

- Awards and funding

- Privacy policy

- Journals and databases

- Locations and contacts

- Membership and professional community

- Teaching and learning

- Help and legal

- Cookie policy

- Terms and conditions

- Get Adobe Acrobat Reader

- Registered charity number: 207890

- © Royal Society of Chemistry 2023

This Feature Is Available To Subscribers Only

Sign In or Create an Account

Thank you for visiting nature.com. You are using a browser version with limited support for CSS. To obtain the best experience, we recommend you use a more up to date browser (or turn off compatibility mode in Internet Explorer). In the meantime, to ensure continued support, we are displaying the site without styles and JavaScript.

- View all journals

- Explore content

- About the journal

- Publish with us

- Sign up for alerts

- Perspective

- Published: 30 January 2023

Green chemistry as just chemistry

- Mary Kate M. Lane ORCID: orcid.org/0000-0001-6208-3903 1 , 2 na1 ,

- Holly E. Rudel ORCID: orcid.org/0000-0003-3535-8697 1 , 2 na1 ,

- Jaye A. Wilson 2 , 3 ,

- Hanno C. Erythropel ORCID: orcid.org/0000-0003-3443-9794 1 , 2 , 3 ,

- Andreas Backhaus ORCID: orcid.org/0000-0002-5314-3799 1 , 2 ,

- Elise B. Gilcher ORCID: orcid.org/0000-0002-0326-5501 2 , 3 ,

- Momoko Ishii 1 , 2 , 3 ,

- Cheldina F. Jean ORCID: orcid.org/0000-0002-5214-874X 1 , 2 ,

- Fang Lin 2 , 4 ,

- Tobias D. Muellers ORCID: orcid.org/0000-0001-8180-6724 2 , 3 ,

- Tong Wang ORCID: orcid.org/0000-0002-9715-9135 1 , 2 ,

- Gerald Torres ORCID: orcid.org/0000-0002-6322-7777 3 , 5 ,

- Dorceta E. Taylor 3 ,

- Paul T. Anastas 2 , 3 , 6 na1 &

- Julie B. Zimmerman ORCID: orcid.org/0000-0002-5392-312X 1 , 2 , 3 na1

Nature Sustainability volume 6 , pages 502–512 ( 2023 ) Cite this article

3590 Accesses

28 Citations

20 Altmetric

Metrics details

- Chemical safety

- Sustainability

Environmental injustices have exposed our current system of reliance on polluting and toxic chemicals and chemistries as untenable and one whose risks and burdens are disproportionately borne by those who are disadvantaged. Aiming for effective interventions to create system-wide change, green chemistry and adjacent approaches are powerful leverage points to deeply address environmental injustices by changing the very nature of the molecular (for example, chemical, material, energy) basis of our economy and our society, obviating the need to rely on procedural systems that can either serve to enable progress or reinforce the status quo.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

24,99 € / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

111,21 € per year

only 9,27 € per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Scientists’ warning on affluence

Evaluating the efficacy and equity of environmental stopgap measures

Equity, technological innovation and sustainable behaviour in a low-carbon future

Taylor, D. E. Toxic Communities: Environmental Racism, Industrial Pollution, and Residential Mobility (New York Univ. Press, 2014).

Bullard, R. D. Dumping in Dixie: Race, Class, and Environmental Quality (Routledge, 1994).

Bullard, R. D., Mohai, P., Saha, R. & Wright, B. Toxic wastes and race at twenty: why race still matters after all of these years environmental justice: making it a reality. Environ. Law 38 , 371–412 (2008).

Google Scholar

Mohai, P., Pellow, D. & Roberts, J. T. Environmental justice. Annu. Rev. Environ. Resour. 34 , 405–430 (2009).

Article Google Scholar

Taylor, D. E. The Environment and the People in American Cities, 1600s–1900s: Disorder, Inequality, and Social Change (Duke Univ. Press, 2009).

Anastas, P. T. & Warner, J. C. Green Chemistry: Theory and Practice (Oxford Univ. Press, 1998).

Erythropel, H. C. et al. The Green ChemisTREE: 20 years after taking root with the 12 principles. Green Chem. 20 , 1929–1961 (2018).

Article CAS Google Scholar

Anastas, P. T. & Zimmerman, J. B. Design through the 12 principles of green engineering. Environ. Sci. Technol. 37 , 94A–101A (2003).

Zimmerman, J. B., Anastas, P. T., Erythropel, H. C. & Leitner, W. Designing for a green chemistry future. Science 367 , 397–400 (2020).

Delegates of the First National People of Color Environmental Leadership Summit. The Principles of Environmental Justice. First National People of Color Environmental Leadership Summit (United Christ of Church, New York, 1991).

Commission for Racial Justice. Toxic Wastes and Race in the United States: A National Report on the Racial and Socio-Economic Characteristics of Communities with Hazardous Waste Sites (United Christ of Church, New York, 1987).

Bullard, R. D. Solid waste sites and the black Houston community. Sociol. Inq. 53 , 273–288 (1983).

Anastas, P. T. & Zimmerman, J. B. The molecular basis of sustainability. Chem 1 , 10–12 (2016).

Newman, M. K. et al. New Perspectives on Environmental Justice: Gender, Sexuality, and Activism (Rutgers Univ. Press, 2004).

Pellow, D. Toward a critical environmental justice studies: black lives matter as an environmental justice challenge. Du Bois Rev. 13 , 221–236 (2016).

Al-Kohlani, S. A. & Campbell, H. E. Extending environmental justice research to religious minorities. Rev. Policy Res. 39 , 90–112 (2022).

Dombey, M. How governments are systematically poisoning indigenous communities and the U.N.’s role. Univ. Miami Int. Comp. Law Rev. Environ. Racism 27 , 131–154 (2020).

Jacobs, B. Environmental Racism on Indigenous Lands and Territories (Canadian Political Science Association, 2010).

Goldsmith, L. & Bell, M. L. Queering environmental justice: unequal environmental health burden on the LGBTQ+ Community. Am. J. Public Health 112 , 79–87 (2021).

Pellow, D. & Vazin, J. The intersection of race, immigration status, and environmental justice. Sustainability 11 , 3942 (2019).

Rockström, J. et al. Planetary boundaries: exploring the safe operating space for humanity. Ecol. Soc. 14 , 32 (2009).

Millennium Ecosystem Assessment. Ecosystems and Human Well-being: Synthesis (Island Press, 2005).

Raworth, K. A Safe and Just Space for Humanity: Can We Live Within the Doughnut? Discussion Paper (Oxfam International, 2012).

Taylor, D. E. The rise of the environmental justice paradigm: injustice framing and the social construction of environmental discourses. Am. Behav. Sci. 43 , 508–580 (2000).

The Routledge Handbook of Environmental Justice (Routledge, 2018).

Anastas, P. T. & Zimmerman, J. B. The periodic table of the elements of green and sustainable chemistry. Green Chem. 21 , 6545–6566 (2019).

Anastas, P. T. & Zimmerman, J. B. The United Nations sustainability goals: how can sustainable chemistry contribute? Curr. Opin. Green Sustain. Chem. 13 , 150–153 (2018).

Keijer, T., Bakker, V. & Slootweg, J. C. Circular chemistry to enable a circular economy. Nat. Chem. 11 , 190–195 (2019).

Kümmerer, K., Clark, J. H. & Zuin, V. G. Rethinking chemistry for a circular economy. Science 367 , 369–370 (2020).

Rittel, H. W. J. & Webber, M. M. Dilemmas in a general theory of planning. Policy Sci. 4 , 155–169 (1973).

Ritchey, T. in Wicked Problems – Social Messes: Decision Support Modelling with Morphological Analysis (ed. Ritchey, T.) 19–29 (Springer, 2011).

Meadows, D. H. in Thinking in Systems Ch. 6 (ed. Wright, D.) 145–165 (Chelsea Green Publishing, 2008).

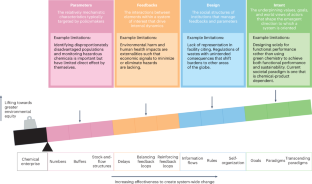

Abson, D. J. et al. Leverage points for sustainability transformation. Ambio 46 , 30–39 (2017).

Aubrecht, K. B., Bourgeois, M., Brush, E. J., MacKellar, J. & Wissinger, J. E. Integrating green chemistry in the curriculum: building student skills in systems thinking, safety, and sustainability. J. Chem. Educ. 96 , 2872–2880 (2019).

Lasker, G. A. & Brush, E. J. Integrating social and environmental justice into the chemistry classroom: a chemist’s toolbox. Green Chem. Lett. Rev. 12 , 168–177 (2019).

Lasker, G. A., Mellor, K. E., Mullins, M. L., Nesmith, S. M. & Simcox, N. J. Social and environmental justice in the chemistry classroom. J. Chem. Educ. 94 , 983–987 (2017).

Matlin, S. A., Mehta, G., Hopf, H. & Krief, A. One-world chemistry and systems thinking. Nat. Chem. 8 , 393–398 (2016).

Kümmerer, K. Sustainable chemistry: a future guiding principle. Angew. Chem. Int. Ed. 56 , 16420–16421 (2017).

Mahaffy, P. G., Matlin, S. A., Holme, T. A. & MacKellar, J. Systems thinking for education about the molecular basis of sustainability. Nat. Sustain. 2 , 362–370 (2019).

Mahaffy, P. G., Ho, F. M., Haack, J. A. & Brush, E. J. Can chemistry be a central science without systems thinking? J. Chem. Educ. 96 , 2679–2681 (2019).

Matlin, S. A., Krief, A., Hopf, H. & Mehta, G. Re-imagining priorities for chemistry: a central science for ‘freedom from fear and want’. Angew. Chem. Int. Ed. 60 , 25610–25623 (2021).

Holifield, R., Porter, M. & Walker, G. Spaces of environmental justice: frameworks for critical engagement. Antipode 41 , 591–612 (2009).

Walker, G. Environmental Justice: Concepts , Evidence and Politics (Routledge, 2012).

Pasgaard, M. & Dawson, N. Looking beyond justice as universal basic needs is essential to progress towards ‘safe and just operating spaces’. Earth Syst. Gov. 2 , 100030 (2019).

Orum, P., Moore, R., Roberts, M. & Sanchez, J. Who’s In Danger? Race, Poverty and Chemical Disasters: A Demographic Analysis of Chemical Disaster Vulnerability Zones (Environmental Justice and Health Alliance for Chemical Policy Reform, 2014).

Lerner, S. Sacrifice Zones: the Front Lines of Toxic Chemical Exposure in the United States (MIT Press, 2010).

Siting of Hazardous Waste Landfills and Their Correlation With Racial and Economic Status of Surrounding Communities (US Government Accountability Office, 1983).

Banzhaf, H. S., Ma, L. & Timmins, C. Environmental justice: establishing causal relationships. Annu. Rev. Resour. Econ. 11 , 377–398 (2019).

Mohai, P. & Saha, R. Which came first, people or pollution? Assessing the disparate siting and post-siting demographic change hypotheses of environmental injustice. Environ. Res. Lett. 10 , 115008 (2015).

James, W., Jia, C. & Kedia, S. Uneven magnitude of disparities in cancer risks from air toxics. Int. J. Environ. Res. Public Health 9 , 4365–4385 (2012).

Johnston, J. & Cushing, L. Chemical exposures, health, and environmental justice in communities living on the fenceline of industry. Curr. Environ. Health Rep. 7 , 48–57 (2020).

Wright, B. H., Bryant, P. & Bullard, R. D. in Unequal Protection: Environmental Justice and Communities of Color (ed. Bullard, R. D.) 110–129 (Sierra Club Books, 1994).

Terrell, K. A. & St Julien, G. Air pollution is linked to higher cancer rates among black or impoverished communities in Louisiana. Environ. Res. Lett. 17 , 14033 (2022).

Landrigan, P. J., Rauh, V. A. & Galvez, M. P. Environmental justice and the health of children. Mt Sinai J. Med. 77 , 178–187 (2010).

Banzhaf, S., Ma, L. & Timmins, C. Environmental justice: the economics of race, place, and pollution. J. Econ. Perspect. 33 , 185–208 (2019).

Elliott, M. R., Wang, Y., Lowe, R. A. & Kleindorfer, P. R. Environmental justice: frequency and severity of US chemical industry accidents and the socioeconomic status of surrounding communities. J. Epidemiol. Community Health 4 , 24–30 (2004).

Friedman-Jiménez, G. Achieving environmental justice: the role of occupational health. Fordham Urban Law J. 21 , 605–632 (1994).

Office of Emergency Management & Office of Land and Emergency Management. Accidental Release Prevention Requirements: Risk Management Programs Under the Clean Air Act, Section 112(r)(7) (US Environmental Protection Agency, 2017); https://www.regulations.gov/document/EPA-HQ-OEM-2015-0725-0734

Chemical Releases Caused By Natural Hazard Events and Disasters - Information for Public Health Authorities (WHO, 2018).

Jafry, T., Helwig, K. & Mikulewicz, M. The Routledge Handbook of Climate Justice (Routledge, 2019).

Wright, B. H. in Race and the Incidence of Environmental Hazards (eds Bryant, B. & Mohai, P.) 114–125 (Routledge, 1992).

Calvert, G. M. et al. Acute pesticide poisoning among agricultural workers in the United States, 1998–2005. Am. J. Ind. Med. 51 , 883–898 (2008).