Presentation Topics For Mechanical Engineering Students

Published by admin on december 13, 2018.

This is a comprehensive list of the best presentation topics for Mechanical Engineering students and researchers. These presentation topics can be used for PowerPoint (PPT), paper presentations, conferences, webinars, seminars, workshops and group discussions. These latest & general topics can be used by students of BE, ME, B Tech, M Tech & mechanical engineering diploma students.

Latest mechanical engineering presentation topics

Artificially Engineered Material Composites

Table of Contents

Artificial Intelligence in Mechanical Engineering

Atomistic Characterization of Dislocation Nucleation and Fracture

Automated Highways

3D Solar cells

Acoustic parking system (APS)

Driverless Cars

Active Electrically Controlled Suspension

Beyond Conventional Mechanical Engineering

Adaptive Light pattern

Advanced Battery and Fuel Cell Development for Electric Vehicles

Adaptive air suspension

Advanced Airbags for more protection

Recent trends in Mechanical Engineering

Recent trends in emission control techniques for engines

Reusable Launch Vehicles

Risks of Nano Engineered Particles

Water Powered Cars

Wireless factories

Alphabetical List of topics

3 Axis Digital Accelerometer

4 Stroke Engines

4-Wheel Independent Suspension

6 stroke engine

Ablative Materials

Abrasive Blast Cleaning

Abrasive Etching

Accelerometer

Acoustic finite elements

Active Control of Near-Wall Turbulent Flow

Active Decoy Systems

Active Front Lighting System

Active roll-over protection system in Automobiles

Adaptive compensation of DTV induced brake judder

Adaptive Cruise Control

Advanced Composite Materials

Advanced Cooling Systems

Advanced Energy Conversion Systems

Advanced Ferryboat Technologies

Advanced Fluid Transport Machinery

Advanced Materials in Automobiles

Advanced offset printing

Advanced Propulsion Methods

Advanced Rocket Motors

Advanced safety features in nuclear reactors

Advances in cutting tool technology

Advances in energy generation

Advances in Gas Turbine

Aerocapture (to reduce the velocity of a spacecraft Aerodonetics)

The aerodynamic design of the wind turbine

Aerodynamics

Aerospace Flywheel Development

Aerospace Propulsion

Aerospike engine

Aerothermal Engineering

Agile manufacturing

Air Augmented Rocket

Air Casters

Air Cushion Vehicles

Air Monitoring

Air pollution from marine shipping

Air Powered Car

Air suspension system

Airbus A380

Aircraft design

Aircraft Egress

Alternate fuels

Aircraft Maneuverability

Aircraft navigation System

Aircraft Propeller

Airport management

All wing Technology

Alternate refrigerants (Non-CFCs Refrigerators)

Alternative Fuel for Vehicles

Alternatives to the current Parking System

Aluminum Alloy Conductors

Alternate Sources of Energy

Analysis and Design Methods of Distributed Sensor

Anti-lock braking system (ABS System)

Antimatter bomb

Antimatter engine

Antimatter propulsion

Antimatter: Mirror of the Universe

Antiroll suspension system

Apache helicopters

Applied Mechanics

ArcJet Rocket (arc jet engine)

Aspheric lenses

Atkinson cycle engine

Automated guided vehicles (using GPS for automobiles)

Automated guided vehicles (without GPS for automobiles)

Automatic sprinkler system

Automatic transmissions

Automation in automobiles

Automation in building agricultural

Automation in building construction

Automobile Air Conditioning

Automobile design: Challenges

Automobile Engineering

Automotive Infotainment

Automotive Mechanics

Autonomous Submarines

Babbitt metal

Ball Piston machines

Ballistic Particle Manufacturing

Ballistic Missile Defense

Best Alternatives to Petrol & Diesel

Battery Electric Vehicle

Bearing Life Measurements

Benchtop wind tunnels

BigDog: The Most Advanced Quadruped Robot on Earth

Bio Mimetic Robots

Bio Robotics

Bio-degradable polymers

Bio-ethanol As Fuel

Biofiltration

Bio-fuels for automobile propulsion

Biological and synthetic materials

Biologically inspired robots

Biomass Fuelled Power Plant

Biomechanics

Biomechatronic Hand

Biomimetics

Bioplastic (100% Organic Plastic)

Bioreactors

Blasting cap

Blended Winged Aircraft

Biometrics: An Unparalleled Security Check System

Boosting Gas Turbine Energy Efficiency

Borewell Rescue Robots

Bose suspension system

Brake Assisting Systems

Brake booster

Breakthroughs in Engine Efficiency

Butterfly valvecatalytic converter

CAD/CAM software packages used in Mechanical Engineering

Camless Engines

Camless engine with the electromechanical valve actuator

Can a ship fly?

Carbon nanotube cloths

Carbon Nanotubes

Car Without Driver

Carbonfibre On F1 Cars

Cargo storage in space

Cell Integration Into A Manufacturing System

Ceramic fasteners

Ceramic-Like Coatings

Clearance of Space Debris

Closed cable-carrier chains for applications exposed to dirt or flying sparks

CNG (Compressed natural gas )

CNG Cars (CNG: Compresses Natural Gas)

Coastal Water Energy System using the Georotor device

Cold or Contact Welding

Collision warning system

Color Tinted Electropolished Surfaces

Combustion Research

Common Rail Direct Injection (Crdi) Engines

Composite materials for aerospace applications

Compound Vortex Controlled Combustion(44)

Compressed Air Energy Storage (CAES)

Compression Tube fittings

Computational fluid dynamics (CFD)

Computational fluid dynamics (CFD) In Weather Forecasting

Computer-Aided Designs (CAD)

Computer-Aided Geometric Design (CAGD)

Computer-Aided Manufacturing (CAM)

Computer-Aided Process Planning (CAPP)

Computer Graphics & Solid Modelling

Computer numerical control for Machine tools

Computer-aided engineering (CAE)

Concept Cars

Concurrent Engineering

Condenser Bushing

Conditional monitoring & fault Diagnosis

The contactless energy transfer system

Contaminant Removal from Soils by Electric Fields

Continuously Variable Transmission

Control of Point of Operation Hazards

Cooling and Lubrication of Engines

Cordless Tools

Corrosion-resistant gearbox

Corrugated Metals

Cruise Missile Technology

Cryogenic Ball Valves

Cryogenic Grinding

Crystalline Silicon Solar Cells

Cushioning Impact in Pneumatic Cylinder

CVCC (Compound Vortex Controlled Combustion)

CVT (Continuously variable transmission)

Cylinder Deactivation

Darkroom machining

Data Fusion for Quality Improvements

Design of an active car chassis frame incorporating magneto rheological fluid

Design, Analysis, Fabrication And Testing of A Composite Leaf Spring

Diamond Cutting Tool And Coatings

Diesel Mechanics

Diesel Particulate Filter

Diffusion Flame Shapes And Thin Filament Diagnostics

Diffusion Welding

Digital manufacturing

Dimple plate heat exchangers

Direct Hydrocarbons For Fuel Cells

Direct Manufacturing

Direct Methanol Fuel Cell

Direct Reduction Iron

DIS (Driver information system)

DNA-based nanomechanical devices

Double-wishbone suspension

Drag Racing

Drive-By-Wire Systems

Driverless Car

Dry ice blast cleaning in food processing industries

Dry Ice Blasting

DSG (Direct shift gearbox)

DTSi (Digital Twin Spark Ignition)

Dual Clutch Transmission

Ductless Induction Ventilation System

Durability in Design

Durable Prototyping

DurAtomic Process

Dynamic Ride Control (DRC)

Dynamic shift program (DSP)

Dynamics of Cutting Viscoelastic Materials

E85Amoeba Organization

Eco-Friendly Fuels

Eco-Friendly Gadgets

Eco-Friendly Home Appliances

Eco-Friendly Vehicles

Eco-Friendly Surface Treatments

Eco-Friendly Technologies

Eco-friendly Water Fuel in Mechanical Engineering

Economical E-Beams

Eddy Current Non-Destructive Testing

Elasto-Capillary Thinning and the Breakup of Complex Fluids

Elecro Hydraulic Sawmills

Electro Magnetic Flowmeters

Elecro magnetic Valves

Electric Automobiles

Electric Cars Concept

Electric Cylinders

Electric power steering units

Electric Rocket Engine

Electricity From Ocean Waves

Electrochemical Machining (ECM) & EBM~

Electrochemistry in material science

Electrokinetic pumping

Electrolytic Hydrogen: A Future Technology for Energy Storage

Electromagnetic Bomb

Electromagnetic Brakes

Electromagnetic Clutches

Electromagnetic Fields and Waves

Electron-beam Machining

Electronic Road Pricing System

Electronic Stability Control/program

Electrostatic precipitator

Embedded Computing in Mechanical Systems

Emerging Technologies in Mechanical Engineering

Emission Control Techniques

Energy Conversion and Management

Energy-efficient turbo systems

Energy-saving motors

Energy transformation

Energy-absorbing bumpers

Engineering Applications of Nylon 66

Engineering for Renewable Energy Systems

Engineering Mathematics

Enhanced Geothermal Systems (EGS

Escapement mechanism

Exhaust Gas Recirculation

Exoskeleton for human performance augmentation

Experimental Fluid Mechanics

Expert Technician System

Explosive Welding

Extra-Galactic Astronomy

F1 Track Design And Safety

FADEC – Full Authority Digital Engine Control

Failure mode evaluation and criticality analysis

Fast breeder reactor technology

FEA in Manufacturing

Finite Element Analysis

Finite element analysis (FEA)

Finite element method (FEM)

Fischer Trophs Process for manufacturing of synthetic fuels

Flapping wing aircrafts

Flexible Manufacturing Systems

Flexible shafts for power transmission

Floating Power Stations~

Floating Windmills

Fluid machinery mand measurement techniques

Fluid Mechanics and Machines

Fluidised Bed Combustion

Flyash Utilisation

Flying on Water

Flywheel Batteries

FMS (Flexible Manufacturing Systems)

Forge Welding

Formula 1 cars: Aerodynamics, Steering Wheel, Safety, Engines

Foundry and Production Technology

Fourth Generation of Biofuels

Fractal Robot

Free Electron Laser

Free Form Modelling Based on N-Sided Surfaces

Freeform Manufacturing

Friction Welding

Frictionless Compressor Technology

Fuel Cell Airplane

Fuel cell-powered Go-Karts

Fuel Cells On Aerospace

Fuel Energizer

Fuels from Plastic Wastes

Full Colour 3D Modelling Using Rapid Prototyping

Functional Nanocrystalline Ceramics

Fused Deposition Modelling

Fusible plug

Future Automobiles

Future Cars

Future of Automobiles

Future of Geothermal Energy

Future of Mechanical Engineering

Future of Portable Power

Fuzzy logic in Aircraft stability

Gaketted Plate Heat Exchnager

Gas Transfer Systems

Gaseous Pyrolysis

Generative Part Structural Analysis

Geo Thermal Energy

Geo-Thermal Energy(19)

Geothermal Power

Glass Making

Global Positioning System~

Globe valves

Green engine

Green Factory

Green fuels

Green Manufacturing

Guided Missile

Guided Missiles

Guyson ultrasonic cleaning machines

HalBach array

Handheld Radiation detector

HANS-In F1 Racing

Harvesting Wave power

Heat Engines and Steam Turbines

Heavy duty Gasoline engines

Helicopters

HHO Hydrogen Fuel Cell

High Altitude Aeronautical Platforms

High angle of attack aerodynamics

High Efficiency Heat Exchanger

High Speed Precise Gear Boxes

High speed Propellers

High speed Railway coaches

HIgh Speed Sliding Doors

High Speed Trains

High speed trains to existing rail routes

High Tides & Low Tides to produce energy

Highly Productive And Reconfigurable Manufacturing System(Hiparms)

High-Temperature Nuclear Reactors for Space Applications

High-volume aluminium pipe system for larger vacuum applications

High-Wire car

Homogeneous charge compression ignition engine

Hovercrafts

Human Artificial organs

Human Powered Vehicle Challenge (HPVC)

Humans and Energy

HVDC Transmission

Hybrid Bikes or Two Wheeler

Hybrid Cars

Hybrid Electric Vehicles

Hybrid energy Systems

Hybrid Synergy Drive

Hybrid vehicles

Hybrid Wind Electrolysis System

Hydraulic Elevators

Hydraulic railway recovery systems

Hydro Drive

Hydro Electricity

Hydro Jetting

Hydro statics

Hydro-Aerodynamic

Hydrodynamics and Heat transfer of Circulating Fluidised Beds

Hydroforming

Hydrogen (water) Powered vehicle

Hydrogen Car

Hydrogen Energy

Hydrogen Fuel Tank

Hydrogen Generation via Wind Power Electrolysis

Hydrogen Management in Refineries

Hydrogen Production using Nuclear Energy

Hydrogen Vehicle

Hydroplanning

Hypersonic Space Planes

HyperTech Engine

Hy-Wire Car

Ice Skating Rink System

Impact hammers

Improved efficiency of gas turbine

Improving aerodynamic performance of an aerospace vehicle

In Mould Lamination Technique

India and Mechanical Engineering

Industrial Cam Lift Hinges

Influence of an iron fuel additive on the performance and emissions of a DI diesel engine

Information Technology in Mechanical Engineering

Infrared Curing And Convection Curing

Injection Moulding

Injection Systems And Emission: Types

Inlet Conditions of An Air Compresor

Instrument Landing System

Intelligent cars

Intelligent Compact drives

Intelligent manufacturing

Intelligent Vehicles

Intelligent Vehicles and Automated Highways

Inter-Continental Ballistic Missile (ICBM)

Inverse Design of Thermal Systems

Ion Drive Engine

Iontophoresis

IT (Information Technology) in manufacturing

IT Application in Complex Syatem Analysis

IT in Mechanical Engineering

Italian Technological Marvels

Jelly Filled Telephone Cables

Jet Powered Boat

Jet Stream windmill

Jetex Engine

Jetropha based biodiesel

JIT (Just in Time)

Kalina cycle

Knowledge Based CAD for Technology Transfer

Laminated Object Manufacturing

Laod Sensing Hydraulics

Laser Material Deposition

Laser radar Guns

LASER Sintering

Laser-Based Remote Detection of Trace Explosives

Latest in hitech petrol fuel injection –GDI (Gasoline direct Injection)

Latest Suspension Systems

Latest Trends in Automotive Engg.& Technology

Lean Burn Spark Ignition Engine

Lean Burn Technology

Lean engineering

Lean to Steer Concept

Lenoir cycle

Light weight material-Carbon fibre

Lightweight Cars: Pros & Cons

Liquid Engineering

Liquid Hydrogen as an Aviation Fuel

Liquid Injection Thrust Vectoring (LITV)

LNG (Liquefied natural gas )

Logistics and supply chain management

Long Term Mine Reconnaissance System

Low Cost Spacecraft Simulator

Low emission gas turbine

Low Gloss ABS system

Low inertia dics clutches

LPG (Liquefied petroleum gas )

LPG as a Fuel (Liquefied Petroleum Gas)

LPG Vs CNG : Truth about Safety Issues

Machine tools vibration, Noise & condition monitoring

Machine vision

Macromolecular Hydrodynamics

Magnetic Bearing

Magnetic Launching

Magnetic Levitation

Magnetic Nanocoposites

Magnetic refrigeration

Magnetic Resonance Imaging

Magnetically driven micro-annular gear pump for metering applications

Magnetorheological Fluids

Magnox Nuclear Reactor

Maintenance Welding

Manufacturing Engineering

Manufacturing Processes

Manumatic transmissions

Marine electric propulsion

Mass airflow sensor

Mass customization: A strategic approach

Mass Rapid Transit System (MRTS)

Material science including Nano-science

Materials used in Space Re-entry Vehicles

Mechanical Behavior of Filament-Wound Pipes

Mechanical Parking System

Mechanical Testing

Mechanical torque limiters

Mechanosynthesis

Mechatronics

MEMS (Micro Electro Mechanical Systems) – a pollution free option for power generation

MEMS Packaging

Mesotechnology

Metal Nanoshells

Metallurgy & Quality Control

Metal-Matrix Composite Processing

Metamorphic Robots

MHD Submarine

Micro- and Nano-Mechanics of Surface Contact Plasticity

Micro Batteries

Micro Electro Mechanical Systems

Micro Fluidic Chips

Micro Gravity

Micro Heat Exchangers

Micro hydraulics

Micro Moulding

Micro Pumps

Micro scale regenerative Heat Exchanger

Micro Turbine

Microair Nozzles For Precision

Microbial Fuel Cells

Microengines for microprocessors

Micro-Epsilon laser profile scanner to inspect weld seams on steel pipes

Microfluidics

Microlithography

Micromachines

Micromanipulating Micromachines

Micromixers

Microprocessor Based IC Engines

Microprocessor based power theft identification

Microscale Breaking Waves And Air-Sea Gas Transfer

Micro-Scale Milling

Microtechnology

MicroTopography

Mileage Improvement Techniques

Miller Cycle Gas Engine

Modeling and simulation

Models Of Random Damage

Modern Air Pollution Control Technologies

Modern Centrifugal Compressors

Modern Manufacturing Processes

Modern Refrigeration Systems: Solar, Thermionic, Vortex Tube

Modified four stroke engine

Modular Cam Locks

Modular conveyor Belts

Modular Gear motor

Modular Workstations

Molecular Engineering

Molecular hinges

Molecular Manufacturing

Molecular nanotechnology

Molten oxide electrolysis

Monobloc pressure jet burner

Mordern Prototyping Methods

Motors Without Mechanical Transmissions

Moulds in Casting of Plastics and Thermoforming

Multi Valve Engine

MultiJack Bolt Tensioners

Multiple material milling platform

MV/HV water spary systems

Nano Electro Mechanical Systems(NEMS)

Nano in navy

Nano Robotic Manipulation System

Nano Robotics

Nano- Robotics and Bio- Robotics

Nano Spreader Cooling

Nanobatteries

Nanocrystalline Thin-Film Si Solar Cells

Nanomaterial

Nanomaterial Based Catalyst

Nanorobotics

Nanoscale Armor

Nanoscale Fractals

Nanotechnology

Nanotechnology & Mechanical Engineering

Nanoventions Micro-optic Modeling

Natural Gas Vehicles (NGV’s)

Negative Pressure Supercharging

New Age Tyres

New Finite Element Analysis for Unsteady 3D Natural Convection

New Level of Nano Precision

New rolling technique for texturing

New Rolling Techniques

New trends in Automobile Design

Night Vision

Non Conventional Methods of Machining

Non Destructive Evaluation Techniques

Non-conventional Energy Sources

Non-Destructive Testing

Nono Fluidics

Nuclear fuel reprocessing

Nuclear Power Potential as Major Energy Source

Nuclear Waste Management

Ocean Thermal Energy

Oil Depletion in the World

Oil Shear brakes

Oil well drilling

Optical trapping and manipulation of small particles

Optimisation of Mechanical Systems

Opto-Electronic Sensor System

Orbit Forming

Orbital Welding

Orbital/Space Mechanics

Organic Plastics

Over-the-wing Engine mount configration

Parallel kinematic machines: Exechon technology

Particle Reinforced Aluminium Matrix Composites

Pasteurization

PDM : Product data management

Pendolina system for railway passenger comfort

Performance Analysis of Manufacturing Systems

Perpetual Motion Machines

Personal Transporters

Photomechanics

Photonic Crystals

Piezoelectric Actuators

Pint Sized Power Plants

Piston less dual chamber rocket fuel pump

Pistonless rocket Engine

Planetary Sciences

Plasma Arc welding

Plasma Science

Plastic recycling

Plastic Welding

PLM: Product lifecycle management

Plug-In-Hybrid Cars

Pneumatic forming

Pneumatics Control Systems

PNG (Piped Natural Gas)

Polymer Nanocomposites

Polymers castings

Porous Burner Technology

Portable biomass stove

Portable Power

Portable X-Ray Fluorescence Analyser

Power frequency magnetic fields

Power From Space For Use On Earth

Power System Contingencies

Powered Industrial Trucks

Practical Fuel-Cell Vehicles

Precision Engineering and practice

Precision manufacturing and Inspection

Prediction of Creep Failure using FEA

Predictive Engineering

Pressure Sensitive Paint

Probabilistic design of mechanical components

Process Automation Techniques

Process Modeling And Simulation

Programmable keyless entry

Progressive Cavity Pump

Propulsion Subsystems

Protection of Communication systems from Solar Flares

Pulsed Plasma Thruster

Pump Noise level reduction methods

Quality Function Deployment

Quantum Chromodynamics

Quantum Mechanics / Quantum Physics

Quick-release terminals for testing or calibration

Radar Guns and Laser radar Guns

Random vibrations

Rapid Design for Lean Manufacturing

Rapid Injection Moulding

Rapid Re-Usable Tooling

Reaction Engineering

Recent Advances in Statistical Quality Control

Recent trends in engine development

Recent trends in manufacturing

Recent Trends in Quality Management

Reduction Technology

Re-Entry of Space Vehicle

Refined IC Engines

Refrigerant circuit with electronic expansion valve metering device

Refrigeration and Air Conditioning

Regenerative brake

Regenerative Fuel Cells

Relativistic quantum field theory (RQFT).

Reliability and risk analysis

Renewable Energy Systems

Renewable Fuel Standard (RFS)

Renewable sugarcane jet fuel

Research Aircrafts

Research and Materials of Armor Design

Resistojet Rocket

Responsive manufacturing

Reverse Engineering

Reverse Engineering in India

Reverse Engineering Worldwide

Rigid Body Dynamics

Ring Gear Maintenance

Risk Analysis of Running Steam Turbines Above Rated Speeds

Robot driven cars

Robotic Assistants For Aircraft Inspectors

Robotic Pioneering

Robotic roller coasters

Robotic Vision

Robotics & AI

Robotics & Automation

Robotics & Industrial Automation

Robotics for Home Applications

Robotics For Millitary Applications

Robots In Radioactive Environments

Rock Mechanics

Rocket Booster Systems

Rocket Powered Aircraft

Roller Pumps

Rotating Parallel Grippers

Rotating Scroll Power Compressor

Rubber Products by Calendaring

Safety And Environment

Safety aspects in nuclear reactor

Safety features of railway rolling stock

Scramjet engine

Screw Fastenings

Scuderi Split Cycle Engine

Seal-less pumps for glue-containing particulates

Secure User Authentication Using Automated Biometrics

Sediment Transport at Hydraulic Jumps

Selective Catalytic Reduction (SCR)

Selective Plating

Self Aware Robots

Self Extinguishing PVC’s

Self Healing Space crafts

Self Monitoring Pneumatic systems

Self Repairing Composites

Self Secured Joints

Self-Assembly For Nano And Micro Manufacturing

Semi automatic transmission

Semi solid Casting

Semi-synthetic cutting fluids

Sensotronic Brake Control System

Sensotronic Braking System

Shape Memory Alloys

Shock Response Spectrum

Simple Constitutive Models for Linear and Branched Polymers

Single Crystal Turbine Aerofoil

Six stroke engines

Sixth sense technology

Skid Steer Loader And Multiterrain Loader

Small Satellites

Smart aerospace structures

Smart Ammunitions

Smart Autoreeling mechanism

Smart Bombs

Smart combustors

Smart Material

Smart material actuators

Smart Materials

Smart Pnuematics

Snake robots

Snaps to Replace Screws

Soft lithography

Solar Cells and Solar Cell Modules

Solar Energy

Solar Energy: Rapidly Evolving Technologies

Solar gadgets

Solar Heat Energy Storage in Phase Change Materials

Solar Ponds

Solar Power Satellite

Solar power Tower

Solar Powered Refrigerator

Solid Base Curing

Solid carbide end mills

Solid –Liquid Separation Technology(73)

Space Craft Propulsion

Space Engineering

Space Robotics

Space Shuttle

Space Shuttle Boosters

Space Shuttle Semisolid Casting

Space Shuttles And Its Advancements

Space stations

Spark Sintering

Special materials for high temperature applications

Special materials for ultra-low temperature applications

Sports Plane

Stealth Radar

Stealth Technology

Steam Sparging

Steer- By -Wire

Stereolithography

Stereoscopic Projection Systems

stratified charge engine

Stress-strain curve & Structural failure

SunGas: Renewable Thermochemical Fuels

Super Air Nozzles

Super Charging

Super Flat Nano Films

Supercase Hardening process

Supercavitation

Superconducting Rotating Machines

Surface Engineering

Sustainable Energy

Sustainable Engineering

Symmetrical All Wheel Drive

Synthetic Aperature Radar

System Identification and Adaptive Control

Systems for Manufacturing Quality Improvement

Systems Modeling and Simulation

Technology-Based Entrepreneurship

Telescopic Lip Dock Levellers

Temperature Resistant Alloys

Tension Control Brake

Test Ranges / Facilities/Readiness

Testing of Welds

The Atomic Battery

The Engineering Research Role in Environmental Noise Control

The Hy-Wire Car

The Truth about Water Powered Cars

Theory of Machines

Thermal Barrier Coatings

Thermal Biomass

Thermal Energy Storage

Thermal Engineering

Thermal Platic Composities

Thermic Turbo Machinery

Thermo Acoustic Refrigeration

Thermo Fluid Mechanics

Thermo Hygrometer

Thermoacoustic refrigerator

Thermodynamics

Thermostatic Refrigerator

Therrmophoresis

Thin Flexible Solar Cells

Thin Vacuum Conveyors

Threadless Couplings

Tidal technology

Tip Tronic Gear transmission

Tire & wheel without pneumatics

Tool Management System

Tool Management System(32)

Topographic Characterization and Modeling of the Precision Surface

Topology Optimization

Total Productive Maintenance

Touch trigger probes

Traction control

Transfer Machines

Transonic aircraft

Trenchless Technology

Trends in welding

Triptronic Automatic Gear Transmission

Tube Hydroforming

Tubeless Tyre

Turbofan Engines

Turbomachines

Two Stage Fuel Injection System

Types of Cars

Types of Engines

Types of Fuels

Tyre ReTreading

Tyre Threading

Ultra Nano Crystallline Diamond

Ultrasonic dispersal of nanomaterials for paints and coatings

Ultrasonic NDE and Characterization of Aerospace Materials

Ultrasonics and Acousto-Optics for the Nondestructive Testing of Complex Materials

Underwater Cars

Underwater Welding

Underwater wind mill

Unmanned Mine Spotter

Use of GPS in automobiles

Use of Mobile Devices in Mechanical Engineering

Use of piezoelectric wafer active sensors for damage identification in aging aircraft structures

Use of space energy for human welfare

Use of Space Technology for Human Welfare

Vacuum Heat Treatment of Materials

Vacuum Work holding

Valvetronic Engine Technology

VANOS (Variable Nockenwellen Steuerung)

Vapor Recovery Systems

Variable compression ratio engine

Variable Flow Pumping

Variable Speed Drives

Variable timing Valve Trains (VTVT)

Variable Valve Timing In I.C. Engines

Vector Calculus

Vertical Axis Wind Turbines

Vertical Landing and takeoff engine

Vertical takeoff and landing aircrafts

Vibration control Techniques

Vibration Tester

vibration-testing technology

Vibro-acoustic modal analysis

Virtual Prototyping

Virtual Reality Visualisation

Viscoelastic behavior of engineering materials

Vision Systems for Safe Driving

Visualization and Computer-Aided Design

Water Fueled Cars

Water jet cutting technology

Water Rocket

Wave Springs

Weapon Engineering / Design

Weber carburetors

Weld flaw detectors

Welding Robots

Wind diesel System

Wind Energy

Wind engineering

Wind From The Sun-Power Plant

Wind turbine with doubly-fed induction generator

Wind-Powered Barbeque Technology

Wireless Energy Transmission

Work Zone Safety

Written-Pole Technology

Zero-Energy Homes

This is all about the best and latest Presentation Topics For Mechanical Engineering Students for power-point as well as Google slides presentations.

Share with friends

Related posts, best topics for 5 minute presentation in 2023.

This post provides best topics for 5 Minute presentation. You can select an appropriate and interesting topic to make your presentation more powerful. Here you can find hundreds of best 5-minute topics for presentation. These Read more…

List of Architecture Presentation Topics (Updated)

Given below is the list of Best Architecture Presentation Topics. This list covers architecture science & engineering topics. These power-point topics will help students as well as researchers for webinars, seminars, conferences, workshops and speech Read more…

Latest Topics For Presentation (Updated)

Below is the list of the latest topics for presentations. These newly updated trending topics can be used for paper presentation, poster presentation, seminars, webinars, conferences, classroom presentations etc. Hope these recent PPT topics will Read more…

- Privacy Policy

- Affiliate Disclosure

Exam Success

150+ Latest Mechanical Engineering Seminar Topics [2023]

Are you looking for the latest mechanical engineering seminar topics? If yes, then you come to the right place. Here, In this blog post, provided a list of the Top 150+ Latest Mechanical Engineering Seminar Topics for mechanical engineering students. This seminar topics list will really help you to select the best mechanical seminar topic for presentation.

These Mechanical seminar topics include a wide range of mechanical engineering such as Automobile Engineering , Production, Mechatronics, Thermal, Robotics, Nanotechnology, and Recent trends that are happening in the technology and Mechanical Industries.

Do share this list of the latest technical seminar topics for mechanical engineering with your mechanical engineering friends. Let’s take a look at this list of mechanical seminar topics.

Latest Mechanical Engineering Seminar Topics for Mechanical Engineering Students

Below is a list of the latest 150+ Mechanical engineering technical seminar topics for students in the mechanical engineering degree and diploma course.

- Advanced Cooling Systems

- Air Bearing

- Air Powered Cars

- Anti-lock Braking System

- Arial Photography Using Remote Flying Robot

- Advanced Rocket Motors

- Advanced Trends in welding

- Active Suspension System

- Advanced Propulsion Methods

- Auto Turning Fuel Valve

- Autonomous Car

- Automatic Emergency Braking

- Air Cushion Vehicles

- Automatic Transmission System

- Adaptive Cruise Control

- Advanced Composite Material

- Active Magnetic Bearing

- Automobile Safety System

- Bio-degradable polymers

- Benchtop wind tunnels

- Biomass Fuelled Power Plant

- Car Speed Control by Blue Tooth

- Catalytic Converter For Cars

- Cryogenic Treatment of Brake Rotors

- Ceramics Disc Brakes

- Cushioning Impact in Pneumatic Cylinder

- Corrosion-resistant gearbox

- Compressed Air Cars

- Computer Intergraded Manufacturing

- Collision Warning System

- Camless Engine with the Electromechanical Valve Actuator

- Combustion Stability in I.C. Engines

- Camless Engine with Electromechanical Valve Actuator

- Digital Manufacturing

- Dual Fuel Engine

- Double-Wishbone Suspension

- Dual Clutch Transmission

- Eco-Friendly Surface Treatments

- Energy-efficient Turbo Systems

- Electronic Fuel Injection (EFI)

- Electrochemical Machining: mechanical seminar topics

- Electromagnetic Brakes

- Floating Solar Power Station

- Flying Car Technology

- Fuel Cells on Aerospace

- Fuels from Plastic Wastes

- FMS (Flexible Manufacturing Systems)

- Friction Stir Welding

- Fuel Efficiency in All-Wheel Drive

- Green Energy Technology

- High-Speed Precise Gear Boxes

- Hydrogen Generation via Wind Power Electrolysis

- Hydraulic railway recovery systems

- Heavy-duty Gasoline engines

- Heat Transfer Through Nano Fluids

- Handfree Driving

- High-Speed Machining

- Hyper Transport Technology

- Hybrid Motorcycles Hybrid Synergy Drive (HSD)

- Hyperloop Technology

- Intelligent Compact drives

- Intelligent Car parking system

- Infrared Curing And Convection Curing

- Independent Suspension System

- Involuntary Train Collision Prevention System

- Jet-Powered Boat

- Low-Cost Anti-lock Braking and Traction Control

- Launching Space Vehicles from Moon

- Laser Ignition For Combustion System

- Laser Beam Welding: Mechanical Engineering Seminar Topics

- Laser Cutting System

- Lean Manufacturing

- Laser Beam Machining

- Low-Cost Wind Power Plant

- Liquid Injection Thrust Vectoring (LITV)

- Load Sensing Hydraulics

- Magnetic Levitation Train

- Marine Electric Propulsion

- Micro Heat Exchangers

- Mechanical Energy Storage

- Multi-Point Fuel Injection System

- Modular Conveyor Belts

- Multi-Valve Engine

- Modern Trends in Automobile

- Methanol Fueled Marine Diesel Engine

- Magnetic Refrigeration

- Magnetic Nanocomposites

- Nanobatteries

- Nanorobotics: technical seminar topics for mechanical engineering

- Night Vision Technology

- Nano Fluids Thermal Applications

- Non-Pneumatic Tyres

- Oil Well Drilling

- Ocean Thermal Energy

- Orbital Welding Orbital/Space Mechanics

- Plastic Welding

- Perpetual Motion Machines

- Plasma Arc Welding

- Plastic Injection Moulding

- Pulse Detonation Engine

- Piston Less Pump

- QuadCopter Drone

- Responsive Manufacturing

- Regenerative Fuel Cells

- Robot-driven Cars (Autonomous cars)

- Rapid Injection Moulding

- Robotic Surgery

- Robots in Radioactive Environments

- Safety Air Bags in Cars

- Solar Powered Satellite (SPS)

- Solid-Liquid Separation Technology

- Solar Powered Refrigerator

- Stirling Engine

- Six Sigma: mechanical engineering technical seminar topics

- Superconducting Rotating Machines

- Space Robotics

- Solar Powered Air Conditioning

- Sensotronic Braking System

- Solar-Powered Aircraft

- Six Stroke Engine

- Synthetic Polymers

- Space Elevator

- Supercharging in Automobile

- Thermal Barrier Coating

- Twin-Turbo or Biturbo

- Traffic Light Control System

- Total Productive Maintenance

- Tidal Energy

- Tool Management System

- Thermo Mech Technology

- Turbines in Silicon

- Tension Control Brake

- Total Quality Management

- Threadless Couplings

- Thermo Acoustic Refrigeration

- Thermal Spraying

- Underwater Welding

- Ultrasonic Welding

- Underwater Windmill

- Variable Length Intake Manifold (VLIM)

- Variable Valve Timing in Internal Combustion Engines

- Vacuum Braking System

- Vapor Absorption Cooling System

- Valvetronic Engine Technology

- Virtual Manufacturing

- Wind-diesel System

- Water Jet Cutting: technical seminar topics for mechanical engineering

- Wireless Energy Transmission

- Wireless Solar Mobile Charger

- Wireless Sensor-Based Motion Control of Mobile Car Robot

Final Words

We hope that you all like the above list of the Latest Mechanical Engineering Seminar Topics for mechanical engineering students. This way, you can select the topic for a seminar from the list.

Also, if you required some more new mechanical seminar topics or mechanical project topics , then let us know via the comment section below, so we will provide some latest mechanical seminar topics for you.

Also Read: –

- Top 200+ Latest Mechanical Engineering Projects Ideas [2023]

- Latest Automobile Engineering Seminar Topics [2023]

- Top 50 Mechanical Companies in Pune

Related Posts

1000+ Best General Seminar Topics for Presentation [Updated 2023]

August 25, 2020 September 10, 2023

Latest Agronomy Seminar Topics 2023

August 21, 2020 April 2, 2023

Latest Agriculture Seminar Topics 2023

August 19, 2020 April 2, 2023

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Search what's trending...

- Entertainment

- Relationships

- Self Improvement

- Trending on Instagram

141 Trending Presentation Topics for Engineering Students

Being a student means giving your best, bringing the best, searching for something new, and presenting the same, especially if you are an engineering student.

For an engineering student, research and presentation become an integral part.

Finding the best topics to research and presenting the same can bring new opportunities for you.

Are you an Engineering student? Are you looking for awesome presentation ideas for your seminar?

We have researched and summarized the internet’s best and latest topics for you.

We have also explained each topic briefly. Here is the post of the interesting ideas for your topics :

Microelectronic Pills

Yes, pills aka (also known as ) medicines. Using a nano-tech baby again to make a pill that is ultra-small and covered with resistant polyether. It has a circuit design, battery, and much more. It is difficult to design and not reusable but has some fair advantages too like determining the pH value of blood, etc. Seems good .

Stepper Motor & its Application

Its applications are 3D printing, medical imaging, milling and many more. It’s just like another motor converting electrical power into mechanical power but what is the difference between this and a simple motor is it is brush-less. You can go on talking about its uses in industry.

Optical fiber communication

You know Jio is working on this. Tata companies already established one in foreign. You have learned its advantages but the only problem is that we have to change the existing systems and then implement this. So it will take little time but it is surely coming in the world in the future. So information can travel faster, you can watch your live streams in seconds. And will be cost-effective .

Learn more about Optical Fiber

Electronic Ballast

It’s is a device that basically limits the amount of electric current in the circuit. It does so by a series connection with a load. It’s simple but highly useful. It does this through the principle of electrical gas discharge. Okay, too much technicals. But it is a very good presentation and one of the good topics in general .

Storage area network

It is a data storage. Has a lot of modern uses. One such use is creating multiple data points and improving data security. It can be easily scaled and has centralized storage.

Traditional and 3D modeling

You make 3 models for documentation and displays. Used in films, computer graphics, gaming, interior design, and many more. And you know this is great technology to see. If you are interested in this topic, you can email any companies who do 3D modeling. And see it in real life. It’s truly an awesome experience to see what goes in the background.

Control of environment parameter in a greenhouse

Natural resources are depleting day by day. So this project deals with using the minimum amount of resources to yield maximum results. Research is done to improve efficiency. WE Truly need this as the population is increasing and crops are not yielding properly.

Cybersecurity

Securing your online presence. Everyone does not become ethical hackers and everyone does not become scammers. So with improvement in technology we need more and more security. This is a vast area to cover, so you can have many opportunities to get a good research and present well.

Communication Network Design

There are many types of Communication Network design- LAN, MAN, WAN, Wireless, Internet. So you can see that this is another broad area to cover. You cannot get to show practical demonstration except for algorithms and network diagrams. That is one disadvantage yet still this is one of the revolutionary inventions of this century .

Thermal & Infrared Imaging Technology

Its applications are in industries, surveillance, construction, and many more. It allows us to visualize the heat emitted. We can understand it’s very important in modern-day comparatively. It’s an interesting and really very good project to work on .

Artificial Eye

Yes, Doctors make an artificial eye to replace our damaged eyes. It’s really jaw-dropping. People can’t seem to find much difference between an artificial eye and a normal one.

Packet Switching chips

The art of sending information in form of packets. Packets are made of a header and a payload. Computer Nerds, you hearing me, right? You will like learning about this. Wait a minute, you may know about this. Even if you know or not, it’s a fascinating topic.

Aeronautical Communications

You guessed it right, aeronautical communication is all about sharing data between aircraft and control centers. This is a highly specialized division. Communications such as aircraft-to-ground, aircraft-to-aircraft, and aircraft-to-satellite.

Performance Evaluation & EMI/EMC Testing of Energy Meter

Energy meters or basically the meter present down at your house (if you are living in an apartment) can be manipulated. You read that. Now we think I wish I knew this before. But it’s illegal. I guess…How? By Electromagnetic interference (EMI) and electromagnetic compatibility (EMC). So this topic is how to evaluate your current properly.

Space mouse

I suddenly remembered Jerry from Tom & Jerry. Sorry. Space mouse is even cooler. It’s like a joystick but to control your 3D models that are present in your virtual screen. I have never controlled a 3D model using a space mouse. But I sure want to see it.

Low energy efficiency wireless

It’s forming a network that is both cheap and efficient. What else we need. This is decent and I will not say very easy but it’s kinda simple. Simply Good. You will need to design a network for this .

Reactive Power Consumption in Transmission Line

Reactive power reduces effective power in the transmission line that comes to your home. But still, it is needed to move active power. So research is about how much reactive power does a transmission line consumes.

Big data visualization

You can visualize data in the form of charts, diagrams, and basically an image. That is exactly what this is all about. Google chart is the best example of Big Data Visualization. There are a plethora of new ways being invented to this .

Brain-Computer Interface

So we connect the brain with an external device . The idea is old yet we do not have a proper working prototype yet. We are still far in human testing. But we are just one the trigger away from improving the speed in this technology. It is by far the most futuristic thing up till now.

Google Home and Google On hub support Mesh Networking. To keep all the devices in connection at the server level. Mesh Radio is still not popular in our country but it is going to be in some years.

Fusion Technology

Nuclei are hit at each with high speed particle guns. Such that they fuse and release energy. Capturing, Controlling, Distributing that power is Nuclear Fusion technology.

Bi-CMOS technology

Bipolar-CMOS is a semiconductor technology for constructing analog and digital logic circuits from both CMOS and Bipolar semiconductor technologies.

Renewable Energy Source Biomass

Biomass is organic material made from plants and animals. Biomass is a renewable energy source because as we grow trees and crops, waste will always exist. Examples of biomass fuels are manure, crops, and some garbage.

Agent-oriented programming

In contrast to object-oriented programming, Agent-oriented programming focuses on the construction of software. There are many research papers going on in this field.

Tsunami warning system

A system developed that could predict the coming of the natural disaster. This is highly important as countless lives and property can be saved. Especially in the eastern part of the world where it’s very dangerous.

Developed by Google, needs no introduction. It revolutionized and gave a tough call to iOS. There are still many Android Developer jobs coming. Going for Android will make you understand your Android’s features more and more.

Smartphone technology

Android and Smartphones are like two sides of a coin. But still, they can be totally new things in smartphones like how your Smartphone is becoming thin day by day.

Touch screen technology

I still remember the old Blackberry and Nokia phone which we used to be amazed at. And suddenly in 2009, I saw my first Samsung smartphone. It was awesome as what caught most of our attention is the touch screen technology which and having no keyboard and stuff. New things to learn here.

CAN-based Higher Layer Protocols and Profiles

It’s the standardized Higher Layer protocol for a number of purposes. There are many research papers on this being made by students from different institutions. There is to lot to say about such protocols.

Feeder Protective Relay

It protects your power grid from faults to supply energy without breaking. Not true for all conditions. But it is still worth our attention looking into this knowledge.

3D image technique and multimedia applications

3D is going to play a vital role in our day-to-day life soon. It’s going to be a movie experience on another level. We may sometimes forget about its vast advantages such as in the fields of architecture, security, manufacturing,etc.

Compressed air Car- A car that can run not on any fuel, not on gasoline, but on air. Yes, AIR. Highly Pressurized air. It does not have a great design or even a normal design . Every now and then we have a new startup that comes and shows out their model. But we clearly see it’s in the phase of research.

Biometric technology

We have seen forensics use it, and we have also seen an average Joe use it sometimes for his company check-in. And pretty much your identification Aadhar card. Right? The main one. Using a Biological way to identify someone in a crowd. This is soon going to be implemented all around the world.

Electronic watchdog

Smart homes in many countries have successfully given a prototype and are being used. So that when an annoying friend comes home and waits for you, you will be informed about it even when you are outside. Sounds good to me. Well and to a lot of investors, as they keep pouring money into R&D (Research and Development) to continually add more features.

Night vision technology

Night vision goggles, which we have used only when we are playing smartphone games. Oh wait we don’t use it there too often. But you must know that almost any other CCTV security camera you bump into as night vision to track people. So it is useful for industries and in the security department.

Advanced technique for RTL

Register Transfer Level (RTL) debugging can help find errors but there was a need for the debugging to be automated when designs became complex. So there are techniques developed to do this very thing. Designs, Figures, Tables are some of the data you need to understand better.

Ultra-wideband technology

It’s a low-range radio technology. It’s like it’s still in the beta version. For any number of years, developers have tried again and again to develop such technology. We are getting closer and closer. Hope your presentation will be the icing on the cake.

Bio-magnetism

Like an animal magnetism. Magnetic Fields by organisms seems innovative but really weird. What could be the future of Bio- Magnetism, we don’t know. But scientists believe that such organisms can be the key for us to understand magnetic fields in a totally different way.

DC Arc Furnace

It’s really a cool project. You use electricity to heat up the arc. It is used in making steel. It has some issues though but it is a very famous project. You can add demonstrations and make the presentation classier.

Global positioning system and its application

You know about GPS and its applications. It looks simple to use but there is a great amount of engineering happening to bring such products. Engineers like you are mainly visionaries.

This is another important topic that is very rare. Few people use these topics. If you wanna be among the few.

Pill camera

Pill are medicines. And the camera is well a camera. So it looks like medicine you swallow into your body. It takes images of your internals -intestine, esophagus, etc. And is very safe.

Something can go wrong only for 1.4% of people. But it is effective and in use. A great yet microscopic presentation.

Animatronics

What is animatronics? Whenever you go to any children’s theme park or any theme park. You will mostly see a puppet-like dinosaur that moves and produces sounds. It is like an automated machine. Disneyland uses these things all the time. This is another new topic.

Built-In Breathing System-used in diving chambers and submarines. BIBS is how you efficiently built a system to breathe in emergency conditions. This is a project in which you will get to learn a lot of simple things in a new manner.

You find a problem and you fix it. You know that. What if you are not a big fan of debugging? But still there are new methods being developed.

You can compile all the new and latest methods. And you can present it. Probably solve a few and find a more efficient method in your presentation. You can give a try.

Turbo codes

You may have heard of it. It was published in the early 90s. They are a class of error-correcting codes. This is a project done by other students also. Not a special topic. But you can get content on the internet done by other people. You can get inspired and add your own version.

Bimolecular Computers

It combines three fields in it- computers, biology and of course engineering. It’s really new. And developers believe it has the potential to revolutionize technology. Many people are researching this very topic. You can find their papers online and derive inspiration.

PC interfaced voice recognition system

Now you don’t have to type your password. You have to speak it. And it will access your computer. Kinda like Shivaji The Boss’s Laptop. This is a pretty neat presentation idea. Many countries have such technology. It is not widely popular in our country yet.

Telephone conversation recorder

The title says it all. There is little content about building a circuit for such a task. While most projects are looking into the future. You may think that being in the smartphone age why should we think of the telephone. Well, it may look simple. Yet it was remarkable technology which we also use in our own smartphones.

Future Satellite Communication

This is BTech Seminar Topic which you may or may not have heard. This is pretty awesome in itself. Communicating via satellite. This technology is defining the way we communicate.

Most of us use the internet. But there is research going on that is absolutely mind-blowing.

Nano-technology

Well, we have talked about a lot of nanotechnologies here and there. So here you focus only on its technology rather than its uses. Making technology smaller is nice. But a lot of effort is needed. You may know about nanotechnology. But really how well do you know about your nanotechnology ?

How about doing some research on it. Who knows you will end up liking it. I highly recommend it.

And you can also see the best tips for an ms PowerPoint presentation to present your topic. 8 Tips to make your Powerpoint Presentation look Professional

Future generation wireless network

You have used data and Wi-Fi. But what is the future of it? Many are trying to understand what the future generation will do. Well, we are talking a lot about the future. We have to. You can read about graphene to start.

Next-generation mobile computing

Mobile is a computer. It is getting advanced every day. So what does the future hold for smartphones? We don’t know yet. Super smartphones, maybe? Well, smartphones came because of android. Yeah android, the same android developed by engineers like you. Who knows, you will be inspired to get that next idea.

Smart antenna for mobile communication

This is another topic that seems old and it is indeed. Papers were written about it in the 90s. And such phones were tested in the market too. You may think what is the use of it now. Well, our defense uses it. Our Army uses it for communication.

Mobile train radio communication

When Radio was working in the old days we used to say over-over. It was one-line communication. Then we improved it to two-way line communication. This is exactly how we do that. Now we use similar technology in our smartphones.

Augmented reality

You know virtual reality(VR). It is looking at things in 3D view. Things that exist in the computer but we will be able to look as if it is lying in your room. Then what is Augmented Reality(AR) you may ask? AR is adding to VR. Now we can not only see it but touch it, feel it and smell it. Sounds amazing to me.

Matter & Energy

You know matter and energy are related to this equation. E = mC squared. This is how atom bombs were based on. Matter turning into energy. This is a century-old discovery yet still relevant in the modern world.

Interactive public display

Another important project topic. Many research papers have been published. When we go to malls, we see large TV-like screens which display ads or videos. It is present in New York’s Time Square. This is going to make our world look smarter.

The Vanadium Redox Flow Battery System

It is difficult to explain easily here. Yet it is truly a good idea. It was demonstrated in the 1980s. We use such a battery system in large power stations today.

Cellular digital packet Data

It is another old technology but its the research is pretty easily found online. Though its services were ended by the Government in 2004. Yet it had speed in data transmission compared to others. Their possible speed was 19.2 kbits/s.

Flexible A C Transmission

Flexible Alternating Current Transmission (or in short FACTS) refers to a system. Basically, when the power comes from the power plant to your house, some power is lost. With FACTS, we have more control ability such that we reduce power wastage. And this system allows our current bill rate not to skyrocket.

Quality of electrical power.

We already spoke about FACTS in the above topic. This is about the quality of that power. To have a steady flow of power. This will go in detail about the study of transmission. And how we need to efficiently use the power generated by the power plant.

Radial Feeder Protection

Basically it’s the same field of protecting power from getting lost. How does it do?When there is a fault like a short circuit we still get power. It is because of Radial Feeder Protection.

Smart dust core architecture.

The goal of smart dust in simple words is to minimize energy. It can get complicated and difficult to explain. Yet it’s circuit diagrams are awesome and its basic architecture is neat.

Traffic pulse technology

Using technology to control traffic more efficiently. This is a modern technology solution to modern traffic problems. Using sensors and proper algorithms is the one solution governments are working on.

Virtual Reality

This future is exciting, especially for streamers and gamers. Those who want to feel and not just see and hear. You must see the VR Headset now and understand it more. About its algorithm, design, function, and reviews. Combine VR with AR. It will take our experience into another dimension.

Blue eyes technology

Blues eyes technology is having computer sensors that read users. And personalize user-experience. Many apple devices are blue Eyes based.

Seminar on artificial passenger

Well many people die in car accidents even when a little drowsiness could cause many innocent lives. This technology is based on sensing the vehicle surrounding and vehicle condition such that it avoids accidents. It’s something everyone is working on.

Telecommunication Network

A telecommunications network is a collection of terminal nodes where links are connected to enable telecommunication between the terminals. It’s a pretty neat idea. There are many types of telecommunication networks.

Organic electronics

It deals with conductive polymers. And conductive molecules. It is more flexible and amorphous in nature than inorganic. Many projects have been made on this topic.

Application of Swarm Robots

Swarm Robots is having its application in medical, defense, etc. There are many uses for these tiny robots. This presentation idea is also used less. Nevertheless, it is still a wonderful tech that will define the very defense systems that are protecting our country.

Autonomic Computing

Autonomic Computing is exactly as it sounds. The Computers manage, allocate resources, and fix errors on its own hiding in the background. This is mostly needed in modern technology to make a more user-friendly experience. Users can be panicked with all the manual computing work. This Autonomic system comes to the rescue.

It’s a microchip inserted into our body. Developed in the early 80s. Used in the medical field. Has a great engineering background even at that time. It amazed a lot of people. you can present about its development and its pros & cons.

The making of quantum dots

What is a quantum dot? A quantum dot is a very small semiconductor that transports electrons. But your main focus is how to make these small semiconductors. You can research about it and find pretty good stuff about it.

74. Very-large-scale integration (VLSI)

Very-large-scale integration (VLSI) is the process of integrating, creating millions of transistors on a single microchip. VLSI technology came into the picture in the 1970s when advanced-level computer processor microchips were under development. It is helping corporations in reducing the circuit size, is cost-effective, and consumes lesser power. VLSI is a successor to large-scale integration (LSI), medium-scale integration (MSI), and small-scale integration (SSI) technology.

DBMS – In today’s digital world, data means everything, and due to the evolution of Database management systems, organizations are gathering, processing, and leveraging more from their work because they can process and leverage tons of data on hand effectively and without much fuss. Its applications are being used across multiple fields, from credit card transaction records to railways system management, Military, Telecom, and Banking.

CMOS stands for “Complementary Metal Oxide Semiconductor.” One of the most popular technologies in the computer chip design industry is broadly used to form ICs or integrated circuits. It makes use of both P and N channel semiconductor devices. This is the dominant semiconductor technology for microprocessors, microcontroller chips, memories like RAM, ROM, EEPROM application-specific integrated circuits (ASICs).

Technology-Related Topics

- Share your thoughts on Artificial intelligence

- How VR(Virtual Reality) works?

- Can online identity be secured?

- What’s new with nanotechnology in the past five years?

- Solar energy: An option or Future?

- What is green technology?

- What’s the latest update about 5G technology?

- How to prevent online data theft and privacy threat?

- How to make learning apps, popular as social media apps?

- How to be safe from cyber-terrorism?

- Concept of genetic engineering

- How do driverless cars work?

- Waste management system in 2021.

- Some facts behind the great innovation of the world.

- New gadgets to expect from fast-growing technology

- Share best suggestions for parking problems.

- What separates engineering from any other career field?

Environmental Topics

- What are you thinking of Biofuels?

- Overpopulations: What can we do about it?

- How to stop food wastages?

- Is pollution prevention possible?

- Sustainable agriculture

- Causes and effects of air pollutions

- Causes and effects of soil pollutions

- Causes and effects of water pollutions

- Discuss climate change

- Global warming: Myth or Real?

- Deforestations: How to stop it?

- Impacts of Ozone layer hole

- Nuclear wastages

- Reasons behind Acid Rain

- Can we save our environment and nature?

- Alternatives to the Papers – A move to the environment and health.

- What makes the perfect urban design and structuring?

IT-related topics for presentation

- Cryptocurrency and Blockchain

- Iron Dome: How does it work?

- Advanced Home security solutions

- The potential threat of robots to humans.

- E-cigarettes

- Staying protected in the digital world

- Touchscreen technology is over, What’s next?

- How does GPS track you?

- Mobile: The biggest threat to your privacy

- IT laws and governance

- Facebook-Whatsapp: Data & Privacy Concerns

- Green computing

- Android vs iPhone

- Voice over Internet Protocol (VoIP)

- Online marketing: Pros and Cons

- How CyberTerrorism is becoming the new threat?

- What’s new in the tech industry?

- Social media privacy: Possibility and the challenges

- After AI, what are upcoming technology trends?

- How to safeguard the user’s privacy on social media?

Non-technical Presentation Topics for Engineering Students

- Engineering and management: The thin line within

- This world needs more engineers: How so?

- How to be more productive and use your time right?

- Technology that we must need, but no one is talking about

- Engineers also have to know how to sell, but why?

- A world without engineers: Importance of the engineers

- Is artificial intelligence also a threat to the engineering field?

- What are the other career options engineers have?

- The role of engineering in society

- What are the challenges for the future engineers?

- How engineering is the best field than others?

So hope this will be helpful for your presentation. This is a sub-article of the main one. You can check the primary article here: 200+ Trending Presentation Topics for Students

Related posts:

- What to Wear to a Coldplay Concert: The Ultimate Guide

- 5 Best Ways to Secure Your Conversations

- 57 Awesome Comments For Songs That Touched Your Soul

- 37 Trending Spotify Playlists For Every Mood

- 5 Reasons Why Smart People Fail

Decoding Gold Loan: Significance of CIBIL score in its approval

18 Benefits of Buying a 1 Crore Term Insurance Policy Early

40 Perfect Comments for Montessori Students

12 Annual Day Speeches for Students, Teachers and Parents in English

Leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Email Address

Save my name, email, and website in this browser for the next time I comment.

Submit Comment

Presentory for Windows

Presentory for mac, presentory online.

Rebrand your approach to conveying ideas.

Differentiate your classroom and engage everyone with the power of AI.

Knowledge Sharing

Create inspiring, fun, and meaningful hybrid learning experiences

Create with AI

- AI Tools Tips

Presentation Ideas

- Presentation Topics

- Presentation Elements

- Presentation Software

- PowerPoint Tips

Presentation Templates

- Template Sites

- Template Themes

- Design Ideas

Use Presentory Better

- Creator Hub

More Details

- Basic Knowledge

- Creative Skills

- Inspirational Ideas

Find More Answers

- LOG IN SIGN UP FOR FREE

- Best Presentation Topics for Engineering Students

- 10 Unique PowerPoint Design Ideas to Captivate Your Audience

- Mastering Business Presentation Skills for Success (Innovative Business Presentation Ideas Updated)

- Creative 8 New Year Presentation Ideas with PowerPoint Themes

- Crafting an Effective PowerPoint Front Page Design for Maximum Impact

- Mastering PESTEL Analysis with PowerPoint: Guide and Templates

- Highlighting The Important Components of Real Estate PowerPoint and How to Make One

- Designing A Sales Plan Presentation for PowerPoint - An Overview of All Details

- Best Presentation Themes to Engage Your Audience in 2023

- 5 Engaging Presentation Topics for University Students

- 10 Interesting Presentation Topics for Students That Will Help You Shine

- Intriguing Topics for Engaging Computer Science Presentations

- Best 10 Selected Current Topics for Presentation to All Audience

- Hot Paper Presentation Topics For CSE

- Elevate Your Skills: Best Topics for Presentation in English

- Top MBA Presentation Ideas To Elevate Your MBA Education

- Full Guide About Best ESL Presentation Topics for Students

- A Complete Guide to Create Company Profile PowerPoint Presentation With Templates

Engineering is considered a complex field. Due to this reason, authorities plan presentations for the progressive learning of students. It is suggested to decide good presentation topics for engineering students. A pre-decided topic can help improve confidence and develop enriched understanding. Moreover, students can pre-practice and keep track of their presentation time and progress.

Presentations are a way to research and learn from a topic. Good topic, content, and delivery are essential to communicate ideas better. In this article, we will discuss paper presentation topics for engineering students . In addition to making a PPT presentation, we'll learn about an AI tool for this purpose.

In this article

- Keys for a Good Engineering Presentation

- Best 10 Topics for Engineering Students

- Presentory for Your Simple and Interesting Engineering Presentation

Part 1: Keys for a Good Engineering Presentation

For an impactful presentation, the right content and graphical displays are required. To prepare a top-notch presentation, one requires a lot of time and expertise. Along with the engineering topic for presentation, other factors contribute to its success. Some of the most prominent key factors for a good presentation are discussed below:

1. Try to Keep it Brief with Data

A common mistake to avoid while preparing a presentation slide is overfilling text. Engineers should keep presentation slides content informative yet brief. People get bored with complex wording and lengthy content. It is suggested to use eye-catching slides that include bullet points.

The addition of bullet points and readable fonts puts the audience at ease. Moreover, you must avoid slang, jargon, and complex terms that can confuse the audience. Another way to achieve the audience's interest is by inserting colorful illustrations in slides.

2. Know Your Audience and the Potential Questions

Before presenting, get to know about your potential audience and their expertise level. It will be helpful in a successful presentation. You can quote relevant examples by knowing the audience's knowledge level and interests. Moreover, it enables you to memorize relevant terminologies and expected questions.

This will enhance your credibility as a presenter and maintain the audience's attention. However, due to interest, your audience will listen to the presentation with attention. Knowing potential questions enables you to create backup slides and enhance confidence.

3. Choose an Interesting Template

Slides are short notes to keep the audience attentive toward the presented topic. A visually appealing slide template is essential to engage them in the presentation. For engineering students, use a template that contains attractive infographics for statistical data. Moreover, use a template that offers complete customization options according to your choices.

In addition, a relative appearance, trending graphics, and layouts make a template unique. Despite the attractive nature of the template, it should be easy to edit to save time.

4. Enhanced Visual Effects

Compelling visual aids grab the audience's attention in seconds. These include transitions and animation in most parts. Engineering students can add icons, symbols, diagrams, and equations. Format your presentation in readable fonts and color palettes. Plus, organize your content according to the topic hierarchy.

Visualize your data through video presentation or 3D animated models. For example, you can make a 3D model of a turbine gas engine for power generation. By visualizing that motor model, you can communicate ideas well.

5. Correct Body Language and Eye Contact

Non-verbal communication is another way to express ideas impactfully. It includes eye contact, hand movements, and facial expressions. Maintaining eye contact while presenting keeps your audience attentive to the concepts.

Keep yourself confident and relaxed through body posture to not forget any information. Lastly, take short pauses while presenting, and take your time while delivering content. Plus, only stare at someone briefly and try to move your face toward the entire audience.

6. Rehearse

Remember that famous quote, "Practice makes a man perfect.” Rehearsal enhances confidence and helps argument effectively. Engineering students are advised to rehearse in front of their friends and teammates. Try to get positive and constructive feedback for positive improvements.

Moreover, while rehearsing, keep track of time and practice managing topics accordingly. Afterward, practice tone of delivery and clear pronoun cation of technical terms . Furthermore, preview slides during rehearsal and clear technical glitches, if any.

Part 2: Best 10 Topics for Engineering Students

Research and presentation play an essential role in engineering students' curriculum. Students have to present in seminars, classrooms, exhibitions, and webinars. Selecting PPT topics for engineering students is a time-consuming concern. After in-depth research, we have summarized the top 10 topics for engineering students. Read below to explore paper presentation topics for engineering students:

1. Medical Uses of Nanotechnology

Nanotechnology can revolutionize treatment, diagnosis, and imaging in the medical field. Nano-particles are engineered to inject drugs directly into the targeted human body. It can rectify risks and side effects. Moreover, nanotechnology enables drug screening, cancer treatment, and many more.

2. Turning Plastic Bags into High-Tech Materials

Environmental problems are dominating every region and becoming hazardous to all life forms. These issues can be addressed through mechanical engineering. The process involves meltdown, extrude, and transformation of plastic into other useful materials.

With chemical engineering, engineers can transform plastic bag particles into molecules. Moreover, you can utilize nanotechnology, polymerization, and molecular structure.

3. Money Pad Future Wallet

An advanced version of the digital wallet is the money pad future wallet. You can discuss biometric data security, hardware designs, contactless sharing, and recipient tracking. Future trends or advancements with machine learning and AI can be explored.

4. 6G Wireless Technology

In regards to cellular networks, 6G wireless technology can be discovered. This technology is yet under development. Engineers are trying to transfer data through waves in GHz and THz. With the support of AI, 6G can improve virtual communication and works up to the speed of 1 Terabit/second.

5. Night Vision Technology

Glasses of night vision technology use thermal imaging that captures infrared light. It enables you to see in dark areas. You can discuss the basic functions, engineering contributions, and night vision devices. Furthermore, future developments and ethical considerations can also be highlighted.

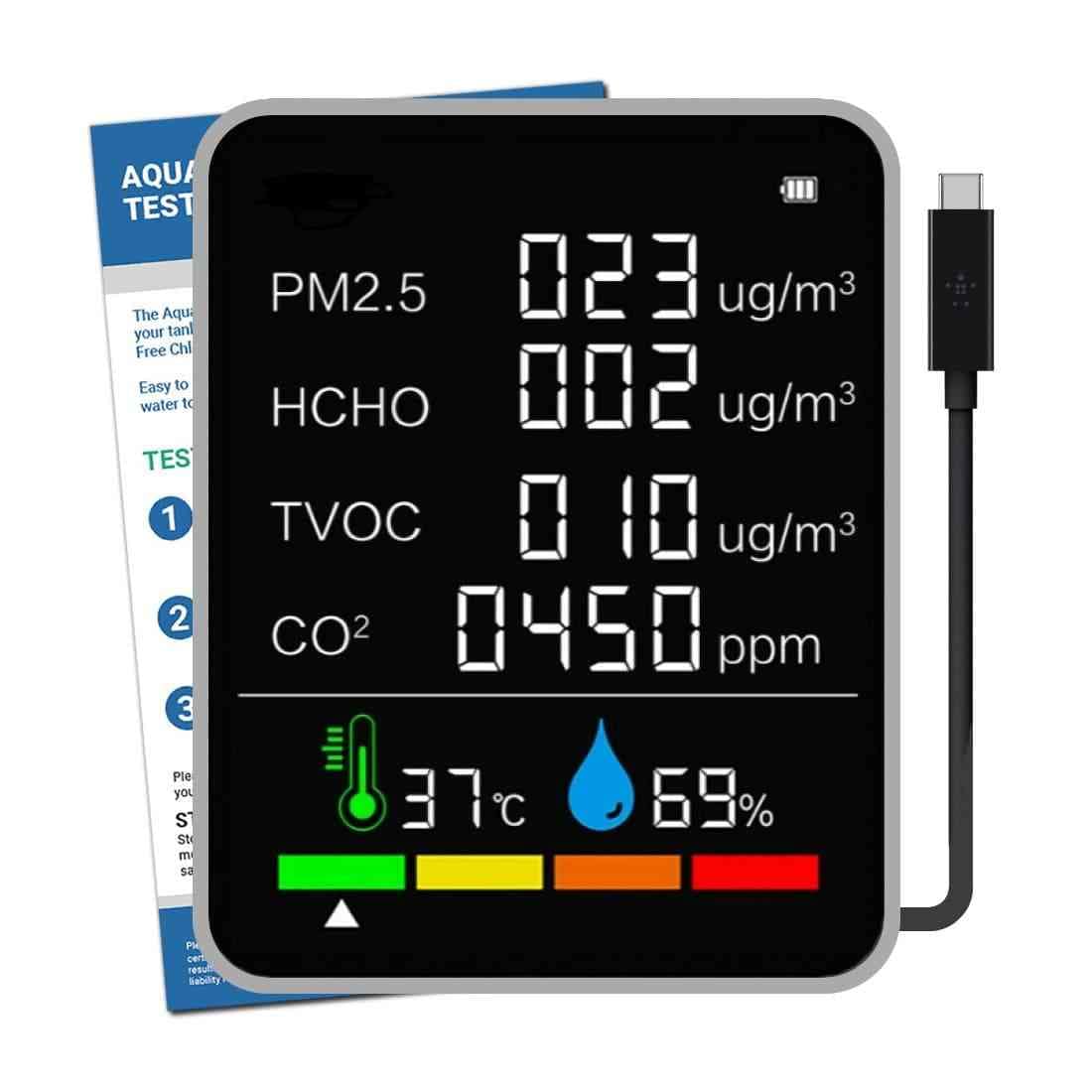

6. Air Pollution Monitor

Certain underdeveloped areas of the globe are facing serious health concerns. Poor air quality index is causing those issues. An air pollution monitor can detect chemical particles and gases. Developing a low-cost air pollution detector can contribute to sustainability.

7. ATM With an Eye

With facial recognition technology, ATMs can match customer's faces with available records. It enhances banks' security systems and minimizes risk caused by stolen ATM PINs. In your presentation, you can discuss future implications and development of this software.

8. Bluetooth-Based Smart Sensor Networks

Discuss how smart sensors input small devices to communicate in your presentation. Moreover, you can highlight its components and implications. Plus, advantages can be discussed that include agriculture and health fields.

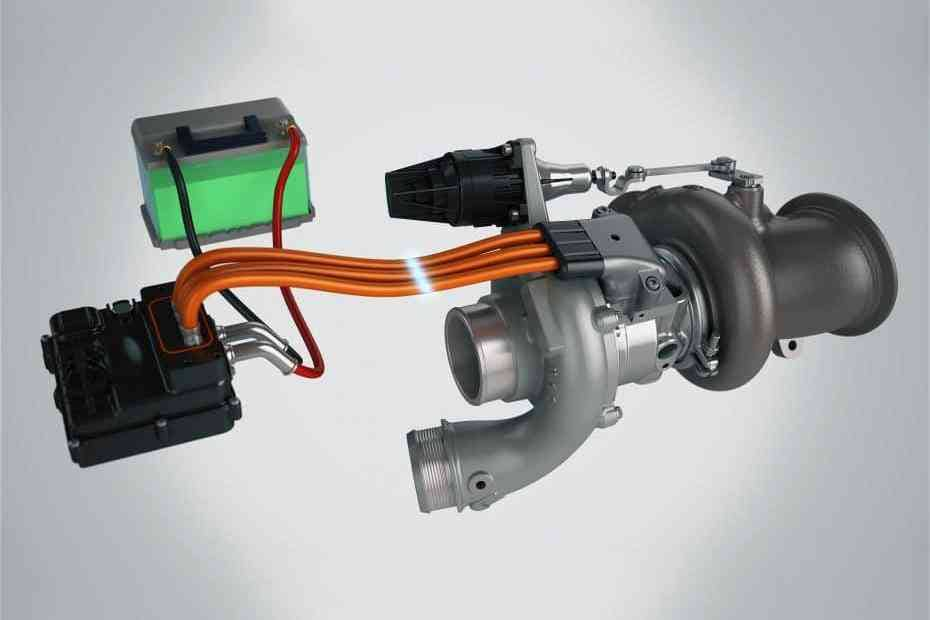

9. Energy-Efficient Turbo Systems

Introduce energy-efficient turbo with machines and engines. You can focus on energy costs and resource utilization. In addition, its efficacy in vehicles and energy consumption can be discussed. Afterward, put real-life examples and challenges to turbo systems.

10. Laser Communication Systems

Laser beams are used to transmit data and replace traditional methods. Define laser communication systems and explain how they operate. You can introduce its applications, like underwater and military communication. Conclude your presentation with the latest trends and challenges.

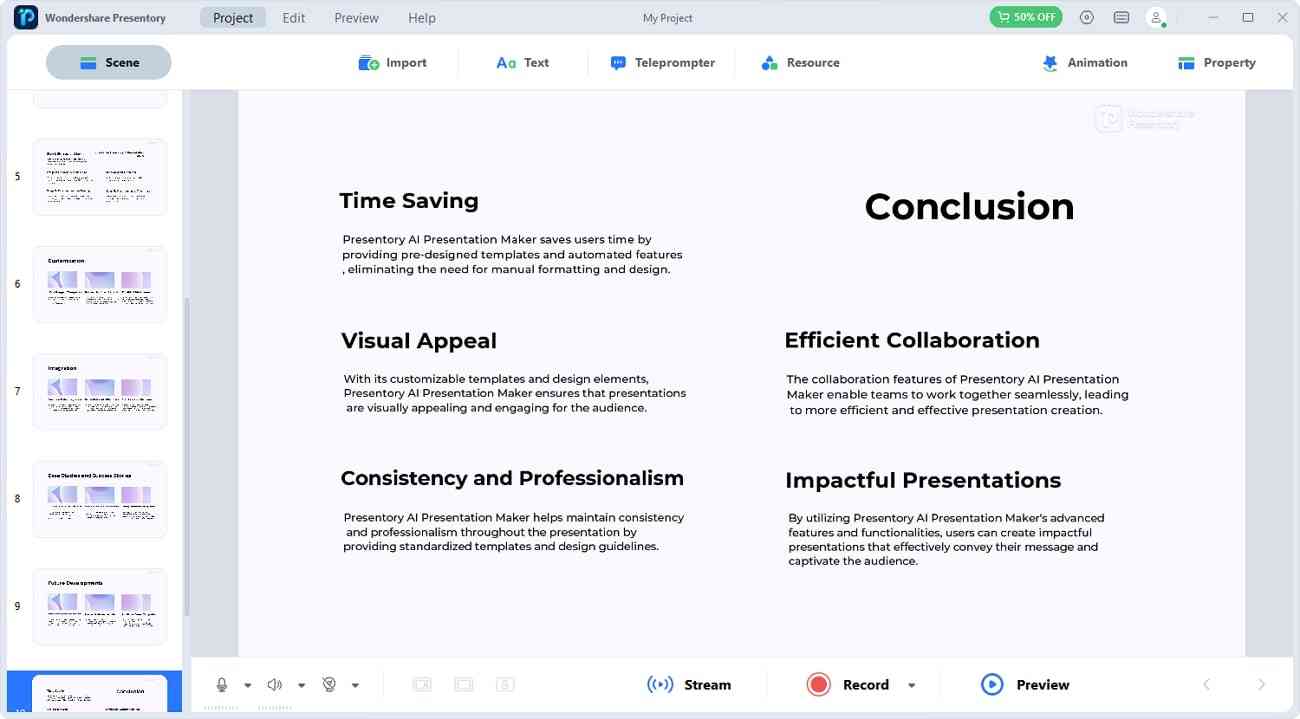

Part 3: Presentory for Your Simple and Interesting Engineering Presentation

Along with the exciting topic, PowerPoint slides matter equally. To grab the audience's attention with impactful presentations, AI tools have proven effective. Wondershare Presentory is a solution for many engineering students. This tool can make PowerPoint presentations, record videos, and stream them online. It has built-in AI and editing features, including visual aids and stunning templates.

This AI operates on cloud tech that allows users the freedom to collaborate online. Apart from this, you can add, remove, or replace video backgrounds. Among those include a dressing room, conference room and cityscapes. Also, you can add stickers and text effects from resources.

Free Download Free Download Try It Online

Key Features

- Import From Multiple Sources: It lets you import any type of media, like images, PPTs, videos, or more. You can edit the already available simple PowerPoint presentation by importing it.